Explosion-proof motors operating in explosive environments often encounter inefficiencies at the IE3 level and experience overheating (temperatures exceeding 80℃, which accelerates component failure), leading to an annual failure rate of over 15%. The Yimai YBX4 explosion-proof motor achieves IE5 efficiency, with a 40% reduction in temperature rise, and has obtained Ex d...

On June 3rd, a delegation of clients from Russia visited Yimai’s factory, embarking on a technical exchange journey. This visit focused on the entire process of precision machining, assembly and testing of motor components, as well as the technological breakthroughs of core products such as end suction pump, submersible...

Legacy shredders encounter significant challenges when processing mixed solids such as tires, metals, and e-waste. These include frequent blade jams (failure rate exceeding 35%), high energy consumption (≥50 kWh/ton), and substantial downtime. The Yimai double shaft shredder addresses these issues through its innovative separation design, specialized cutting tools made from advanced...

Electric fire pumps often fail during blackouts, with delays exceeding 60 seconds and battery life lasting less than 30 minutes. This significantly escalates risks in skyscrapers and chemical plants. The Yimai fire fighting diesel engine, characterized by its high torque and robust power output, can rapidly achieve the rated working...

Legacy water plants are constrained by prolonged construction periods (12-18 months), extensive land requirements (3-5 times larger than modular solutions), and high operational costs (accounting for 40% of total treatment expenses). These limitations impede the achievement of water security and hinder rapid emergency response. The Yimai modular integrated water plant transforms...

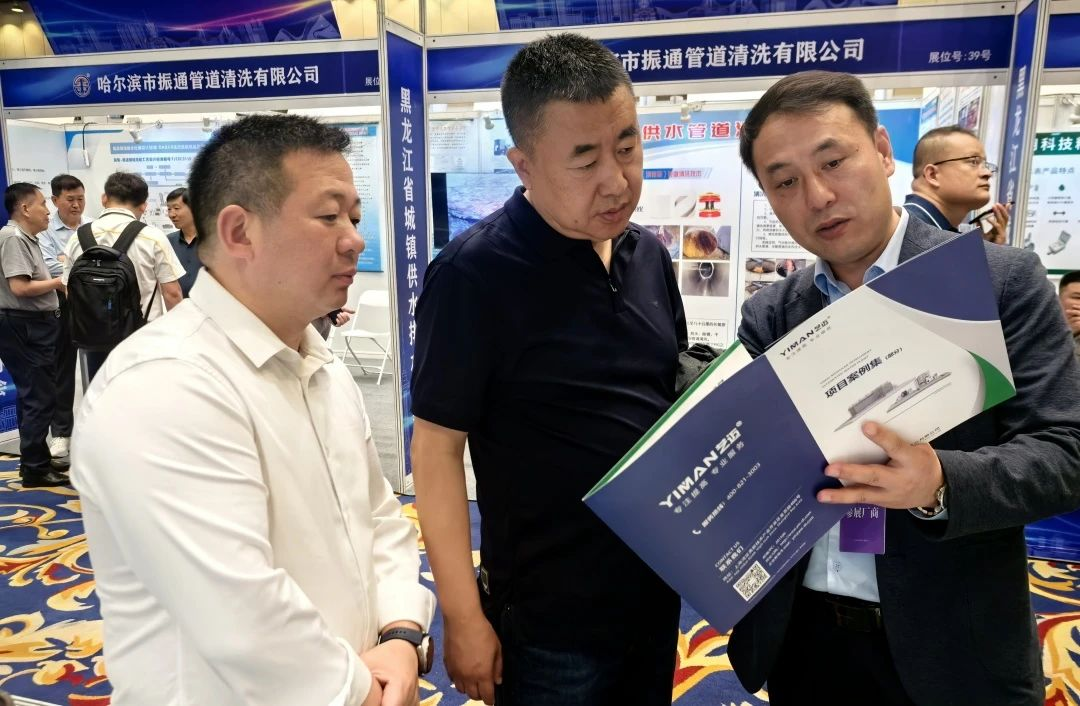

In the current era of high-quality transformation and development of urban water supply and drainage, Shanghai Yimai, with its profound technological accumulation and innovative momentum, has always remained at the forefront of the industry. From May 26th to 28th, 2025, the First member representative Conference of the Second Term...

Legacy sewage pumps encounter significant operational challenges, including fiber entanglement (resulting in over 40% clogging), frequent seal failures (with an annual failure rate of 25%), and excessive energy consumption (accounting for 30% of the plant’s electricity usage). These issues lead to costly downtime in both municipal and industrial applications. The...

Legacy sewage lifting systems struggle with frequent clogging (<20mm solid handling), high energy use (35% of plant electricity), and odor leaks, especially in aging communities and underground complexes. The Yimai sewage water elevating system solves these challenges with shredding technology and airtight intelligent controls—boosting solid handling to 50mm, cutting energy consumption...

Motors operating in explosive environments, such as petrochemical and mining industries, often encounter insufficient protection (limited to Ex d IIB), overheating issues (which accelerate insulation degradation), and low efficiency (≤85% under IE1). These challenges can result in safety incidents and significant energy waste. The Yimai YBX3 explosion-proof three-phase asynchronous...

Traditional single-suction pumps in high-flow applications like municipal water supply and industrial cooling suffer from low efficiency (≤80%), excessive axial force (bearing lifespan <2 years), and time-consuming maintenance (>8 hours per repair). The Yimai split casing double suction pump addresses these challenges with symmetrical double-suction impellers, split-case housing, and high-strength...