Electric Motor Controller Selection: A Practical Guide to Finding Reliable Electric Motor Suppliers

When your municipal pump station goes down at 2 AM, you quickly learn that choosing the right electric motor controller and reliable electric motor suppliers isn’t just about price – it’s about system reliability. We’ve seen too many facilities struggle with controller failures or incompatible motor-controller pairs because they didn’t ask the right questions upfront.

This guide walks you through the practical considerations for selecting motor controllers and suppliers, with a specific focus on energy-efficient and explosion-proof applications in water treatment and pumping systems.

Image Suggestion: System structure diagram showing the relationship between VFD controller, motor, and pump in a municipal water system

What You Need to Know Before Selecting Electric Motor Controllers?

An electric motor controller does more than turn your motor on and off. It regulates speed, protects against electrical faults, and directly impacts your system’s energy consumption. For water pumping applications, we typically recommend variable frequency drives (VFDs) because they allow precise flow control while reducing energy costs.

Before you start comparing controllers, map out your system requirements. What’s your motor’s rated power? Will it operate in a hazardous area? Do you need remote monitoring? We find that 60% of controller selection problems stem from incomplete initial specifications.

Your controller must match three critical motor parameters: voltage rating, frequency, and current capacity. A 380V-50Hz motor (standard in most regions) requires a controller rated for at least 110% of the motor’s full-load current to handle startup surges.

Key Technical Specifications for Motor Controllers in Water Systems

When we specify controllers for pump systems, these are the non-negotiable technical requirements:

Protection Features: Look for IP55 or higher protection grade to match your motor’s enclosure. Controllers in outdoor pump stations need weatherproof enclosures. Built-in overload protection, phase loss detection, and ground fault protection are essential – don’t rely on separate protection devices if you can get them integrated.

Control Modes: V/F control works for most pumping applications. For precise flow control in booster water systems, we specify closed-loop vector control. This mode maintains constant pressure even when demand fluctuates, which matters for high-rise building supply.

Communication Protocols: Modern municipal systems need Modbus RTU or Profibus connectivity at a minimum. Remote monitoring isn’t optional anymore – it’s how you catch problems before they become emergencies.

Ambient Temperature Range: Standard controllers handle -10°C to 40°C. If your pump house isn’t climate-controlled (and most aren’t), verify the controller’s thermal management system can handle local extremes.

Energy-saving Permanent Magnetic Electric Motor Requirements

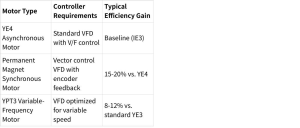

Energy-saving permanent magnetic electric motor technology represents a significant efficiency jump over standard asynchronous motors. These motors use permanent magnets in the rotor instead of induced magnetism, which eliminates rotor losses.

We’ve measured power consumption reductions of 15-20% when replacing IE3 efficiency asynchronous motors with permanent magnet synchronous motors in constant-torque pump applications. For a 75kW pump running 16 hours daily, that’s roughly 50,000 kWh saved annually.

The controller for a permanent magnet motor needs specific capabilities. It must provide precise rotor position feedback control – typically through a built-in encoder. Standard V/F control won’t work. You need vector control with position sensor feedback.

Heat management becomes critical because permanent magnets lose magnetism at high temperatures. Your controller should include motor temperature monitoring with automatic derating or shutdown at preset limits.

Explosive Protection Electric Motor Certification Standards

Explosive protection electric motor applications demand controllers with matching hazardous location ratings. This isn’t an area for shortcuts – certification gaps create liability issues and genuine safety risks.

For explosion-proof motors like our YBX3 or YBX4 series, the controller must have certification for the same hazardous area classification. In Zone 1 environments (where explosive atmospheres can occur during normal operation), we use controllers with ATEX or IECEx certification marked for Zone 1 or Division 1.

The controller enclosure must prevent any spark or hot surface from igniting the surrounding atmosphere. This typically means explosion-proof housings or purged/pressurized enclosures. Don’t assume a controller marketed as “industrial” meets explosion-proof requirements – verify the certification markings.

Cable entries require special attention. Standard cable glands won’t maintain the explosion-proof integrity. You need certified cable glands with proper thread engagement and flame path dimensions. We’ve seen installations fail inspection because someone used standard glands to save $200 on a $50,000 system.

How to Evaluate Electric Motor Suppliers

Finding reliable electric motor suppliers requires looking beyond price lists. Here’s what separates suppliers you can trust from those who’ll leave you stranded:

Technical Support Capability: Call their technical line before you order. Can they answer specific questions about motor-controller compatibility? Do they understand your application? A supplier who can’t explain why a IE4 three-phase asynchronous motors needs different controller settings than a YPT3 motor won’t be helpful when you’re troubleshooting at midnight.

Certification Documentation: Request copies of motor certifications before purchase. For explosion-proof motors, you need the full ATEX or IECEx certificate, not just a claim of compliance. We verify serial number traceability – each motor should have documentation linking it to batch testing results.

Delivery and Lead Time Transparency: Standard motors should ship within 2-3 weeks. Custom configurations (special voltage, mounting, or materials) need 6-8 weeks. Suppliers who promise everything in “2 weeks” either have massive inventory (unlikely) or will miss deadlines.

After-Sales Support: What happens if a motor fails during installation? During the warranty period? After warranty? We only work with suppliers who stock spare parts locally and provide same-day technical support response.

Integration Between Controllers and Motors: What Most Engineers Miss

Controller-motor integration problems cause more startup delays than any other issue. Here are the critical points most engineers overlook:

Motor Nameplate vs. Controller Parameters: The controller must be programmed with accurate electric motor data – rated power, current, speed, power factor. Using default parameters might get the motor running but kills efficiency and protection capability. We create a commissioning checklist that includes photographing the motor nameplate and verifying each parameter in the controller.

Cable Length and Voltage Drop: VFD output voltage includes high-frequency components that cause voltage drop in long cables. For cable runs over 50 meters, we upsize conductors or add output reactors. This is especially important for submersible sewage pumps where cables run 20-30 meters to the control panel.

Grounding Systems: Controllers generate electrical noise that requires proper grounding. A single-point ground connection from controller to electric motor frame prevents ground loops. We use dedicated ground conductors sized at minimum 50% of the phase conductor size.

Motor Thermal Protection: Don’t rely solely on controller thermal modeling. Install PTC thermistors or PT100 sensors in motor windings and connect them to controller thermal inputs. This provides actual temperature data instead of calculated estimates.

Common Controller-Motor Compatibility Issues

We troubleshoot these problems weekly in the field:

Motor Overheating: Usually caused by carrier frequency mismatch. Standard motors need 4-6kHz carrier frequency. Running at higher frequencies (12-16kHz for reduced noise) increases electric motor heating. Solution: Match carrier frequency to motor design or specify variable frequency speed regulating three-phase electric motors like YPT3 that handle higher frequencies.

Bearing Failures: VFD-induced bearing currents damage motor bearings in 6-18 months instead of the expected 5-10 years. This happens when high-frequency common-mode voltages create circulating currents through bearings. Solution: Install insulated bearings or shaft grounding brushes. For electric motors above 30kW, we specify this as standard.

Nuisance Trips: Controller trips on overcurrent during pump startup, even though the current is within ratings. Usually caused by incorrect acceleration ramps or current limit settings. Solution: Extend acceleration time to 15-20 seconds and set the current limit to 150% of motor’s rated current.

Communication Failures: Controller loses communication with SCADA system intermittently. Usually, it is electromagnetic interference from VFD or poor grounding. Solution: Use shielded communication cables with grounded shields at one end only, and separate them from power cables by at least 300mm.

Maintenance and Support Expectations from Motor Suppliers

Set clear expectations with your supplier before purchase:

Warranty Terms: Standard motor warranty is 18 months from delivery or 12 months from commissioning, whichever comes first. For explosion-proof motors, verify that warranty covers recertification if the motor is opened for repairs. Some suppliers void certification warranty if you don’t use their service centers.

Spare Parts Availability: Critical parts – bearings, seals, thermal sensors – should be available from local stock. We require suppliers to commit to a 5-day maximum delivery for wear parts and 15 days for major components like stator windings.

Technical Training: Suppliers should provide commissioning support for the first installation and training for your maintenance team. This isn’t just “nice to have” – improper installation voids warranties and creates safety issues with explosion-proof equipment.

Field Service Response: For critical municipal systems, we contract annual maintenance agreements that include preventive maintenance visits and priority emergency response. Response time should be 4 hours maximum for systems in urban areas.

Final point

Selecting the right electric motor controller and supplier comes down to matching technical requirements precisely, verifying certifications thoroughly, and establishing support relationships before you need them. Don’t compromise on explosion-proof certifications in hazardous locations. Calculate total lifecycle costs, not just purchase price – energy-efficient motors and controllers pay for themselves in 18-24 months for continuous-duty applications.

We’ve learned that supplier technical capability matters more than catalog size. A supplier who understands pump system integration and can explain controller parameter settings will save you far more money than one who simply offers the lowest price.

Industry Insight about Electric Motor Controller

The water industry is moving toward integrated motor-controller packages rather than separate component procurement. This shift is driven by two factors: efficiency regulations that require optimized motor-controller pairing, and digitalization demands for remote monitoring capabilities.

Our permanent magnet synchronous motors paired with dedicated vector control drives deliver 15-20% energy savings compared to IE3 asynchronous motors with standard VFDs – based on actual measurements in our municipal pump station projects. This efficiency gap will only widen as pump systems face increasingly variable demand patterns from smart water management systems.

For suppliers and facility managers, this trend means selection criteria must evolve beyond motor specifications alone. You need to evaluate the complete drive system – motor, controller, sensors, and communication architecture – as a single engineered package. Suppliers who can provide integrated systems with factory-optimized parameters and remote diagnostics capability will dominate municipal and industrial projects within the next 3-5 years.

This explains why we engineer our YE4 motors with controller-specific winding designs and provide pre-programmed parameter sets for major VFD brands. It’s not just convenient – it’s essential for achieving rated efficiency in real-world installations where parameter tuning expertise is limited.

Need Help Selecting the Right Motor and Controller?

Shanghai Yimai has solidified its role as a trusted motor manufacturer in China, renowned for its flexible and customized motor solutions. Our technical team works directly with you to adapt standard models or develop new designs, ensuring optimal performance for your specific industry application. This collaborative approach, combined with our robust manufacturing capabilities, delivers unparalleled value and a distinct competitive edge to your projects.

Frequently Asked Questions

Q: How do I verify that an electric motor controller is compatible with explosion-proof motors?

Check that both motor and controller have matching hazardous location certifications (ATEX, IECEx, or NEC classification). The controller must be rated for the same zone/division as your installation location. Don’t rely on “industrial rated” claims – verify actual certification documents and ensure the controller enclosure maintains explosion-proof integrity. Our YBX4 explosion-proof motors require controllers with minimum Zone 1/Division 1 certification.

Q: What energy savings can I expect from a permanent magnetic electric motor compared to standard asynchronous motors?

Real-world installations show 15-20% energy reduction for permanent magnet synchronous motors versus IE3 asynchronous motors (like our YE4 series) in constant-torque pump applications. For a 55kW pump operating 8,000 hours annually, this translates to approximately $4,700 saved per year at $0.12/kWh electricity cost. The payback period is typically 18-24 months after accounting for the higher initial controller cost.

Q: What makes a reliable electric motor supplier for industrial pump applications?

Technical support capability is the primary indicator. A reliable supplier can answer specific questions about motor-controller integration, provides complete certification documentation, maintains local spare parts inventory, and offers commissioning support. We recommend requesting technical references from similar pump installations and verifying warranty terms before purchase. Response time for technical support should be same-day, not 3-5 business days.

Q: Can I use the same controller for different motor types like asynchronous and permanent magnet motors?

No. Standard asynchronous motors (YE3, YE4 series) work with V/F control VFDs, while permanent magnet synchronous motors require vector control with encoder feedback. Using the wrong control mode causes efficiency loss, overheating, or motor damage. Variable-frequency motors like our variable frequency speed regulating three-phase electric motors need controllers with specific carrier frequency and voltage regulation settings. Always verify controller compatibility with your specific motor type before purchasing.

Q: How do I prevent bearing damage from VFD-induced currents in large motors?

For motors above 30kW powered by VFDs, install either insulated bearings on the non-drive end or shaft grounding brushes. This prevents high-frequency common-mode voltages from creating circulating currents through bearings. Use shielded VFD output cables with properly grounded shields, and maintain minimum 300mm separation from other power cables. These measures extend bearing life from 6-18 months back to the expected 5-10 years. Our YE4 motors above 37kW include insulated bearings as standard for VFD applications.