8 Things about Explosion-Proof Three-Phase Asynchronous Motor You Need to Know

In many industrial sectors—from oil and gas to specialized chemical production and certain Wastewater Treatment Systems—equipment must operate in atmospheres where flammable gases, vapors, or dust are present. In these critical environments, a single ignition source can trigger a catastrophic event. This is why the Explosion-Proof Three-Phase Asynchronous Motor is not merely an option; it is a critical safety mandate backed by stringent international standards like ATEX and IEC Ex. At Shanghai Yimai, we deliver motors engineered to mitigate this extreme risk while simultaneously upholding the highest levels of performance and high-efficiency.

Defining the Explosion-Proof Three-Phase Asynchronous Motor and its Safety Mandate

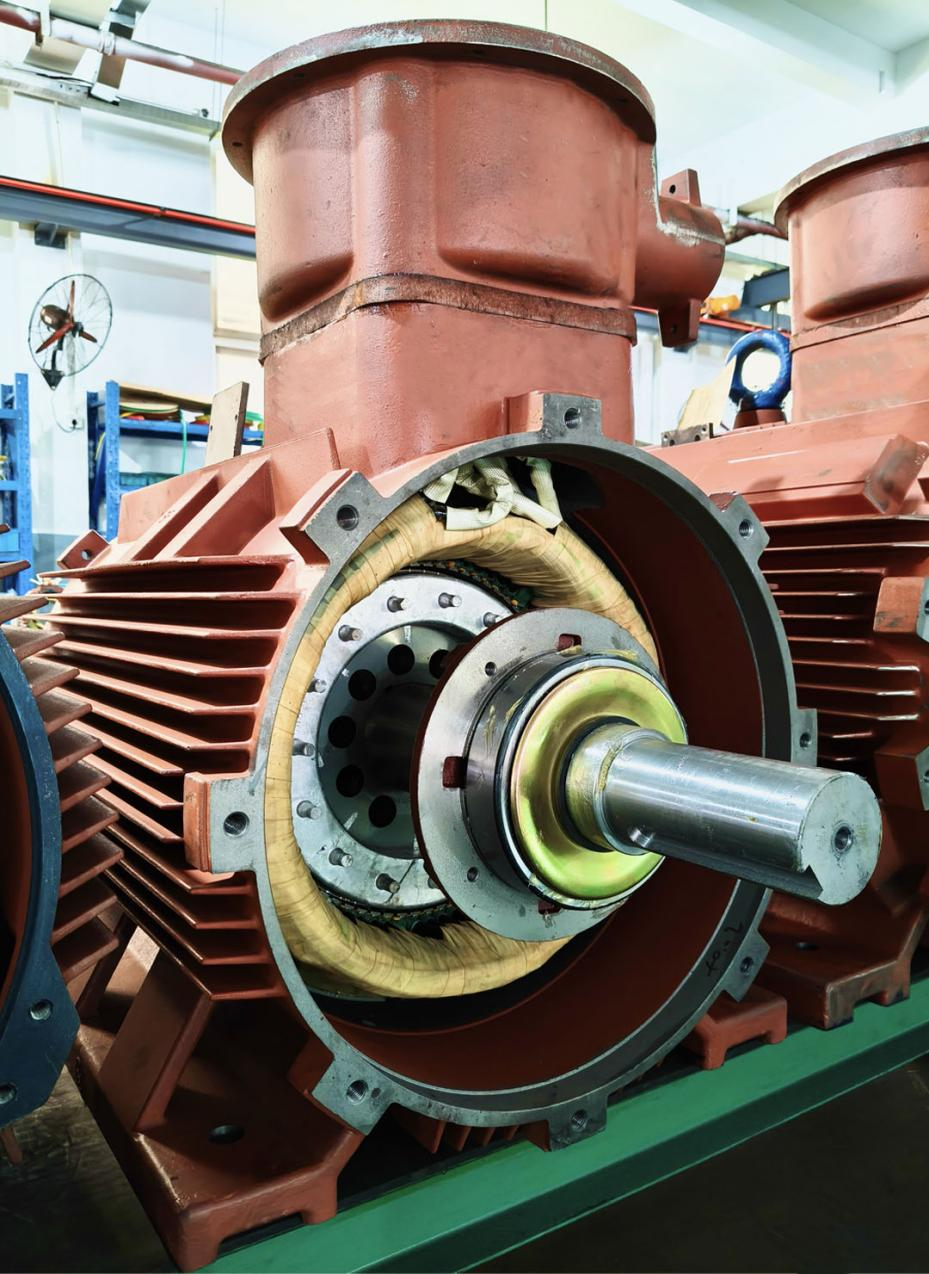

An Explosion-Proof Three-Phase Electric Motor is a specialized version of the industrial workhorse, specifically designed to contain any internal ignition event safely. These motors, including our acclaimed YBX3 explosion-proof three-phase electric motor and YBX4 explosion-proof three-phase electric motor, utilize a heavy-duty, certified housing known universally as a flameproof enclosure. The fundamental purpose of this design is not to prevent an internal explosion entirely, but to ensure that if a gas-air mixture ignites inside the motor casing, the resulting blast pressure is fully contained. The crucial mandate is to prevent the flame or hot gases from escaping the enclosure and igniting the surrounding hazardous atmosphere. Every motor we provide for these applications is designed, manufactured, and tested to meet these precise safety requirements, making them indispensable components for Motor Safety in Hazardous Locations. We understand that reliability in a Three-Phase Asynchronous Motor is always important, but in a hazardous area, it is paramount to life and compliance.

How the Flameproof Enclosure Ex d Guarantees Motor Safety in Hazardous Locations

The core principle behind the Flameproof Enclosure Ex d technology is containment and quenching. When an internal explosion occurs, the motor casing must be mechanically robust enough to withstand the resulting high-pressure wave without rupture. The enclosure is not perfectly sealed. There are precise, engineered gaps at mating surfaces, such as between the housing and the bearing caps or at the shaft seal. These microscopic pathways are known as flame paths. As the hot, expanding gases from the internal explosion attempt to escape, they are forced through these narrow gaps. The heat transfer to the cold metal surfaces of the enclosure cools the gases below their auto-ignition temperature before they can exit into the external atmosphere. This quenching mechanism prevents the external ignition, ensuring the Explosion-Proof Three-Phase Asynchronous Motor fulfills its safety role perfectly. This design is the cornerstone of Motor Safety in Hazardous Locations, demanding meticulous manufacturing tolerances that Shanghai Yimai consistently meets. Maintenance of these critical flame paths is non-negotiable; even a hairline scratch or corrosion can compromise the integrity of the Ex d protection.

Understanding Hazardous Area Classification for Explosion-Proof Motors: Zone 1, Zone 2, and Gas Groups

Proper selection of an Explosion-Proof Three-Phase Electric Motor hinges on correctly identifying the hazardous area classification defined by standards like IEC Ex or ATEX. This classification dictates the level of protection required from the motor. We simplify the understanding for our clients by focusing on two key elements: the likelihood of a hazard and the nature of the explosive substance.

- Zone Classification:This defines the risk level. Zone 1 represents an area where an explosive atmosphere is likely to occur during normal operation, requiring the highest level of motor safety certification. Zone 2 is for areas where the explosive atmosphere is unlikely to occur, and if it does, it will persist for only a short period. Our YBX3 explosion-proof electric motors and YBX4 explosion-proof electric motors are certified for these critical zones.

- Gas Groups:This categorizes the explosive substance. Motors rated for Group IIB are suitable for areas containing common industrial gases like ethylene or propane. For more reactive gases like hydrogen, the more stringent Group IIC classification is required. Matching the motor’s certification (Ex d IIB) precisely to the location’s classification is a fundamental step in achieving Motor Safety in Hazardous Locations and maintaining compliance.

Selecting the Correct Temperature Class T4 for Optimal Explosion-Proof Three-Phase Asynchronous Motor Safety

Beyond the containment of the internal explosion, the Explosion-Proof Three-Phase Asynchronous Motor must also prevent ignition by excessive surface temperature. This is where the Temperature Class T4 becomes the most important safety parameter. The motor’s external surface temperature must never exceed the auto-ignition temperature of the surrounding flammable gas or vapor.

The most widely adopted standard in industrial settings is the Temperature Class T4. This designation means that the maximum permissible surface temperature of the motor will not rise above 135℃, even under worst-case operating conditions. This Temperature Class T4 rating is critical because it safely covers the ignition temperatures of the majority of solvents and chemicals commonly encountered in a chemical plant or refinery. We utilize precise thermal management techniques to ensure that even with our higher high-efficiency designs, the Explosion-Proof Three-Phase Electric Motor always respects this limit. Failure to maintain this temperature class due to poor power quality or thermal overload compromises the motor’s safety certification and creates an immediate ignition risk, failing the primary objective of Preventing Explosion in Chemical Plants.

Explosion-Proof Motors in Industrial Wastewater Treatment and Oil-Water Separation

The necessity of the Explosion-Proof Three-Phase Asynchronous Motor extends well beyond petrochemicals. In municipal and industrial wastewater handling, areas near settling tanks, anaerobic digesters, or sludge dewatering facilities often generate combustible gases like methane or hydrogen sulfide. Furthermore, facilities managing industrial effluents, particularly those processing food waste or specific chemicals, frequently require specialized equipment. For instance, pumping stations handling sludge for a Double Screw Continuous Press or those serving an oil-water separation system must use certified explosion-proof motors to drive the Submersible Sewage Pump or Single Screw Pump. We provide integrated solutions that are compliant with Zone 1 and T4 standards, ensuring that even in the presence of these unpredictable biogases, our pumping solutions remain safe and reliable. Our design focus is on maintaining continuous operation for these critical Wastewater Treatment Systems while never compromising the Motor Safety in Hazardous Locations.

The Dual Role of IP55 Protection and IC411 Cooling in Explosion-Proof Motor Design

An effective Explosion-Proof Three-Phase Asynchronous Motor design must maintain robust protection against environmental ingress and precise thermal management. Our motors, including the YBX3 explosion-proof motor and YBX4 explosion-proof motor, feature IP55 protection as a standard specification. This high degree of IP55 protection ensures that the motor is resistant to dust and low-pressure water jets, which is vital for maintaining the integrity of the insulation and preventing surface contamination that could impair cooling. The buildup of dust on the exterior fins, for example, directly affects the ability of the motor to dissipate heat, potentially pushing the surface temperature beyond the permissible limits of the Temperature Class T4 rating.

Coupled with this is the IC411 cooling method, the standard for Totally Enclosed Fan Cooled (TEFC) motors. The fan is crucial for constantly moving air over the motor fins to manage the winding temperature. In explosion-proof designs, precise thermal management is even more critical. We design our cooling systems to work efficiently within the confines of the heavy-duty enclosure, ensuring that the necessary heat is removed to maintain the required temperature class and extend the life of the insulation class materials. This pairing of IP55 protection and IC411 cooling is non-negotiable for reliable Motor Safety in Hazardous Locations.

Installation, Maintenance, and VFD Integration Protocols for YBX3/YBX4 Series

The certified rating of an Explosion-Proof Three-Phase Asynchronous Motor can be instantly voided by improper installation or unauthorized maintenance. As experts in this field, we enforce strict protocols for our YBX3/YBX4 series:

- Certified Cable Glands:Only explosion-proof, certified cable glands that match the motor’s Ex rating must be used. Standard glands will fail to seal the enclosure and cannot quench a flame front, immediately compromising safety.

- Strict Flame Path Protocol:Disassembly and reassembly of the flameproof joints must be conducted by certified personnel using specialized torque settings. The flame paths must remain clean, free of paint, and free of corrosion.

- VFD Integration Considerations:When utilizing a Variable Frequency Drive (VFD) with our YBX4 explosion-proof three-phase electric motors, we must account for the increased voltage spikes and the reduced airflow at low speeds. We specify VFD-rated, temperature-monitored motors to ensure that the motor remains compliant with the Temperature Class T4 across the full operating range. This VFD Integration must always prioritize Motor Safety in Hazardous Locations over simple process control.

In hazardous locations, the motor’s primary function is safety containment, driven by its certification. We only supply Explosion-Proof Three-Phase Electric Motor units that have been rigorously tested and certified to meet the required Group (e.g., Group IIB) and Temperature Class T4 for your specific industrial environment. This adherence to standards is what allows technical teams to operate confidently, knowing they are proactively Preventing Explosion in Chemical Plants and other sensitive facilities.

The Transition to YBX4 and VFD-Controlled Explosion-Proof Systems

The ongoing demand for reduced energy consumption has pushed the hazardous location market to move rapidly toward high-efficiency solutions. While the YBX3 explosion-proof three-phase electric motor Classification (typically IE2/IE3 efficiency) provided robust safety, our focus is now on the YBX4 explosion-proof electric motor, which aligns with the Super Premium Efficiency (IE3/IE4) standard. This technological shift allows us to maintain the highest level of Motor Safety in Hazardous Locations while significantly reducing operating costs.

Furthermore, we are increasingly integrating these high-efficiency motors with VFD controlled booster systems. Although VFD Integration introduces challenges—specifically the potential for increased motor heating due to voltage harmonics—the energy savings are substantial, particularly in pump systems that require variable flow. We address the thermal challenge by specifying VFD-compatible YBX4 explosion-proof three-phase electric motors with reinforced insulation class and thermal protection, ensuring that even under VFD control, the motor remains compliant with the required Temperature Class T4 rating across all operating speeds, fulfilling the promise of both safety and high-efficiency.

Contact us Now!

Need help ensuring your motor fleet complies with ATEX or IEC Ex standards, or are you considering an efficiency upgrade to our Variable frequency speed regulating EX three-phase electric motor? Contact our experts for a personalized solution and a full safety compliance audit for your hazardous location applications.

Shanghai Yimai invites you to source wholesale electric motors directly from our sophisticated motor factory in China. This integrated approach allows us to offer competitive pricing and guaranteed supply consistency. We provide a diverse portfolio of motors suitable for bulk procurement, ensuring you receive high-value products backed by comprehensive technical support and swift delivery.

Frequently Asked Questions (FAQs)

What is the number one maintenance mistake that compromises an Explosion-Proof Three-Phase Asynchronous Motor?

The number one mistake is failing to use certified components or improper reassembly after maintenance. Specifically, using an incorrect, non-certified cable gland instantly voids the motor’s Flameproof Enclosure Ex d certification. Maintenance personnel must ensure that all fasteners are torqued correctly and that the critical flame paths are free of debris to ensure continued Motor Safety in Hazardous Locations.

Does the Temperature Class T4 rating change if the motor is controlled by a VFD?

Yes, VFD control can impact the thermal performance of the Explosion-Proof Three-Phase Asynchronous Motor, particularly at low speeds where the IC411 cooling method is less effective. Although the motor’s Temperature Class T4 certification remains the same, the VFD settings must be managed to prevent the motor’s surface temperature from exceeding the 135∘C limit. For critical applications, we recommend Variable frequency speed regulating EX three-phase electric motors equipped with thermal protection devices linked directly to the drive.

How is the YBX3 Explosion-Proof Motor Classification relevant to the IE efficiency standards?

The YBX3 explosion-proof three-phase electric motor Classification generally corresponds to the IE2 or IE3 efficiency standard, focusing on achieving a safe enclosure while meeting a baseline level of efficiency. In contrast, the modern YBX4 explosion-proof three-phase electric motor pushes efficiency to the IE3/IE4 level. The evolution from YBX3 to YBX4 represents the industry’s commitment to both Preventing Explosion in Chemical Plants and maximizing energy savings simultaneously.

Keywords

Explosion-Proof Three-Phase Asynchronous Motor, YBX3 Explosion-Proof Motor Classification, Motor Safety in Hazardous Locations, Preventing Explosion in Chemical Plants