Selecting the Right Electric Motor OEM, ODM Manufacturer A Guide for Global Buyers

How to Select the Right Electric Motor OEM&ODM Manufacturer?

After working with hundreds of global buyers over the past decade and a half, I’ve learned what really separates exceptional electric motor OEM, ODM manufacturer partnerships from disappointing ones. It’s not just about price—though that matters—it’s about finding a partner who truly understands your technical needs and can deliver consistently, batch after batch.

As someone who’s built our factory from the ground up and earned the “National Specialized, Refined, and New Little Giant Enterprise” recognition here in China, I want to share what I wish every global buyer knew before they started their search. This isn’t marketing speak—these are the real factors that determine whether your China electric motor manufacturing partnership will succeed or leave you scrambling for alternatives six months down the line.

What I’ve Learned About Evaluating Electric Motor OEM China Factory Technical Capabilities

Here’s something most buyers get wrong:

They focus on whether we can make their motor, not whether we can make it consistently well. In my experience, the difference lies in understanding the engineering fundamentals behind what we do.

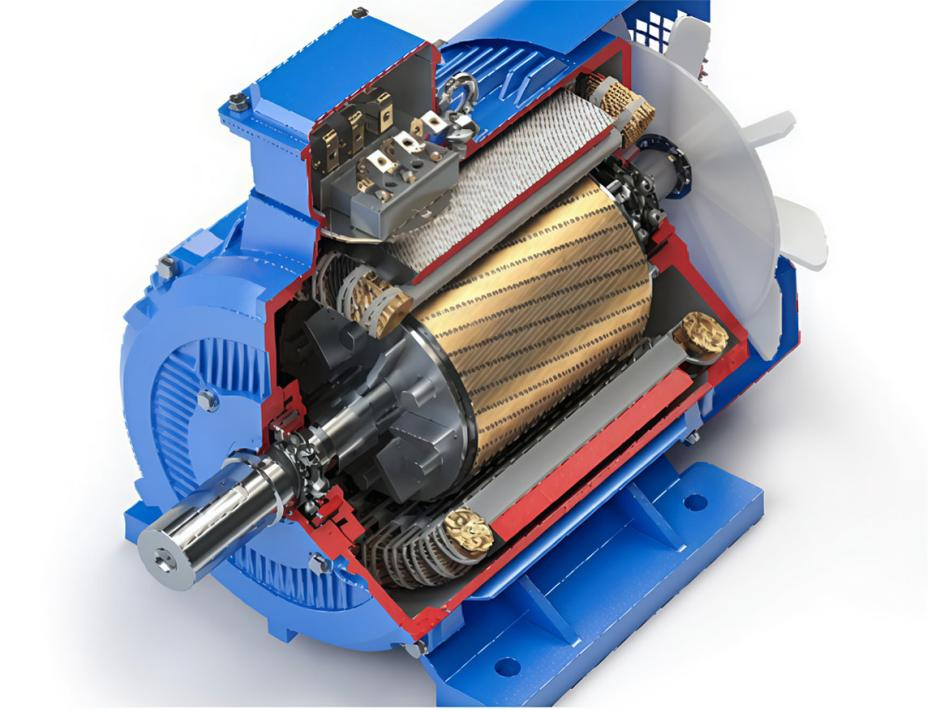

When I walk potential partners through our facility, I always start with standards compliance. We’ve built our entire operation around IEC60034/IEC60072 specifications because I learned early on that global buyers need motors that work seamlessly with their existing systems. There’s no room for “close enough” when you’re dealing with industrial applications.

Let me give you specifics about what we guarantee on every motor that leaves our floor:

- Protection Grade IP55: I chose this as our standard because most of our clients’ applications involve dust and moisture exposure. We test every unit to ensure it handles both.

- Cooling Method IC411: Fan-cooled, totally enclosed design. I’ve seen too many motors fail from overheating to compromise on thermal management.

- Insulation Class F: High thermal tolerance because your motors need to perform reliably under demanding conditions, not just in ideal laboratory settings.

Whether you need a straightforward Three-Phase Asynchronous Motor or a complex Variable-Frequency Motor with custom control integration, we maintain these standards across every production run. That consistency is what transforms a supplier relationship into a true electric motor OEM, ODM manufacturer partnership.

Why Quality Control Defines the Success of Electric Motor ODM Partnerships in China?

I’ll be blunt: quality assurance is where most manufacturers cut corners, and it’s where most partnerships fall apart. When you’re working with an electric motor ODM China supplier on custom designs, you’re trusting us with your reputation. We don’t take that lightly.

Here’s how we approach quality control, and what you should expect from any serious manufacturer:

Full Traceability: Every motor we produce has a complete record—raw materials, production batch, assembly technician, test results. When something goes wrong (and occasionally it does), we can trace the issue back to its source within hours, not weeks.

Mandatory Testing: We perform dynamic balancing, vibration analysis, no-load and full-load current testing, and temperature rise verification on every single unit. These aren’t spot checks—they’re standard procedure. Your specifications aren’t suggestions; they’re requirements.

Standards Adherence: We maintain strict compliance with global certifications because your products need to meet safety and efficiency standards worldwide, not just pass factory acceptance tests.

What sets us apart as an trustful electric motor OEM China factory is transparency. We share our test data, explain our processes, and welcome audits. We control our entire manufacturing chain, from winding to final assembly, regardless of mounting configuration (IMB3, IMB5, IMB35). When quality issues arise—and they sometimes do—we own them and fix them quickly.

The Difference Between OEM and ODM for Electric Motors

After years of working with global buyers, I’ve noticed many don’t fully understand the difference between OEM and ODM services. Let’s break it down based on real projects we’ve handled:

OEM (Original Equipment Manufacturer)

When you come to us with complete design specifications and detailed drawings, you’re looking for OEM services. You own the design, and we handle manufacturing. Think of it as “build exactly what’s on paper.” We focus on material standardization, production efficiency, and volume scalability. You maintain full control over intellectual property.

ODM (Original Design Manufacturer)

This is where we take your performance requirements and create a custom solution using our existing motor platforms. You might need a motor with specific mounting dimensions or terminal box positioning. We modify our proven designs to meet your needs. The IP becomes shared—you own the application, we own the core design modifications.

As an experienced electric motor OEM, ODM manufacturer, we handle both approaches professionally. For OEM projects, we excel at high-volume production with tight component control. For ODM work, our engineering team adapts our platforms—adjusting frame sizes, pole configurations (2 Pole, 4 Pole, 6 Pole), or cooling systems—to match your specifications.

The key is choosing the right approach for your situation. If you have established designs and need production scale, OEM makes sense. If you need faster time-to-market or lack internal motor design resources, ODM is your path forward.

Why Choose us as Your Electric Motor OEM&ODM Supplier?

Let’s address the elephant in the room: many global buyers worry about supply chain reliability and IP protection when working with manufacturers in China. These concerns are valid, and I respect clients who ask tough questions upfront.

Supply Chain Stability

Our “National Specialized, Refined, and New Little Giant Enterprise” designation isn’t just a title—it represents operational excellence and financial stability. But here’s what really matters for your supply chain:

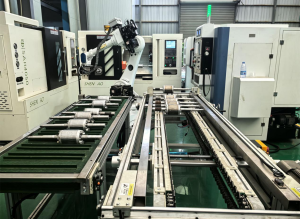

We control our core manufacturing processes internally. Winding, balancing, painting, final assembly—we do it all in-house. This reduces our dependence on external subcontractors who might face their own disruptions.

We maintain strict material standardization following IEC specifications. This makes our components easier to source globally and reduces variability that could impact your production schedules.

We offer flexible logistics solutions and handle complex international documentation. When you need electric motors shipped to multiple destinations with different certification requirements, we make it happen seamlessly.

Intellectual Property Protection

IP protection starts with legal frameworks, but it extends to operational culture. Here’s how we protect your designs:

Comprehensive NDAs cover all shared specifications, drawings, and testing data. These aren’t boilerplate agreements—they’re customized to your specific IP concerns.

For sensitive OEM projects, we use dedicated production lines and assembly teams. Your designs never mix with our standard products.

We restrict engineering drawing access to screened personnel on a need-to-know basis. Not everyone in our facility can access your proprietary information.

Trust develops through demonstrated secure operations. We’ve built our China electric motor manufacturing partnership reputation by protecting client IP as carefully as we protect our own.

Understanding that one size does not fit all, our Yimai specializes in providing customized motor solutions. Whether powering specialized pumps or unique industrial machinery, our technical team collaborates with you to design and manufacture motors that meet precise specifications for torque, speed, and environmental conditions. Partner with us for flexible, high quality electric motors that drive your specific success.

Frequently Asked Questions

How do you protect intellectual property for custom electric motor OEM designs?

We start every electric motor OEM project with comprehensive NDAs that cover all technical specifications and proprietary information. Beyond legal protection, we implement physical safeguards including segregated manufacturing areas and restricted access to proprietary drawings. Your technical specifications remain confidential throughout the entire production cycle.

What’s the minimum order quantity for electric motor ODM China factory projects?

MOQ depends on the motor specifications and required tooling. For standard modifications using existing platforms, we can work with smaller quantities. Completely new designs requiring custom tooling need larger initial commitments to justify R&D and manufacturing setup costs. We always discuss MOQ requirements during our initial consultation to ensure alignment with your budget and timeline.

Can you provide international compliance certifications as an electric motor OEM, ODM China manufacturer?

Absolutely. Our manufacturing processes comply fully with IEC60034/IEC60072 specifications, and we provide necessary certifications (including CE marking) for global markets. We work closely with clients to achieve specific regional certifications required for their target markets. Our certification experience spans North America, Europe, and Asia-Pacific regions.

Keywords

electric motor OEM,ODM manufacturer electric motor OEM China factory,electric motor ODM China supplier,China electric motor manufacturing partnership