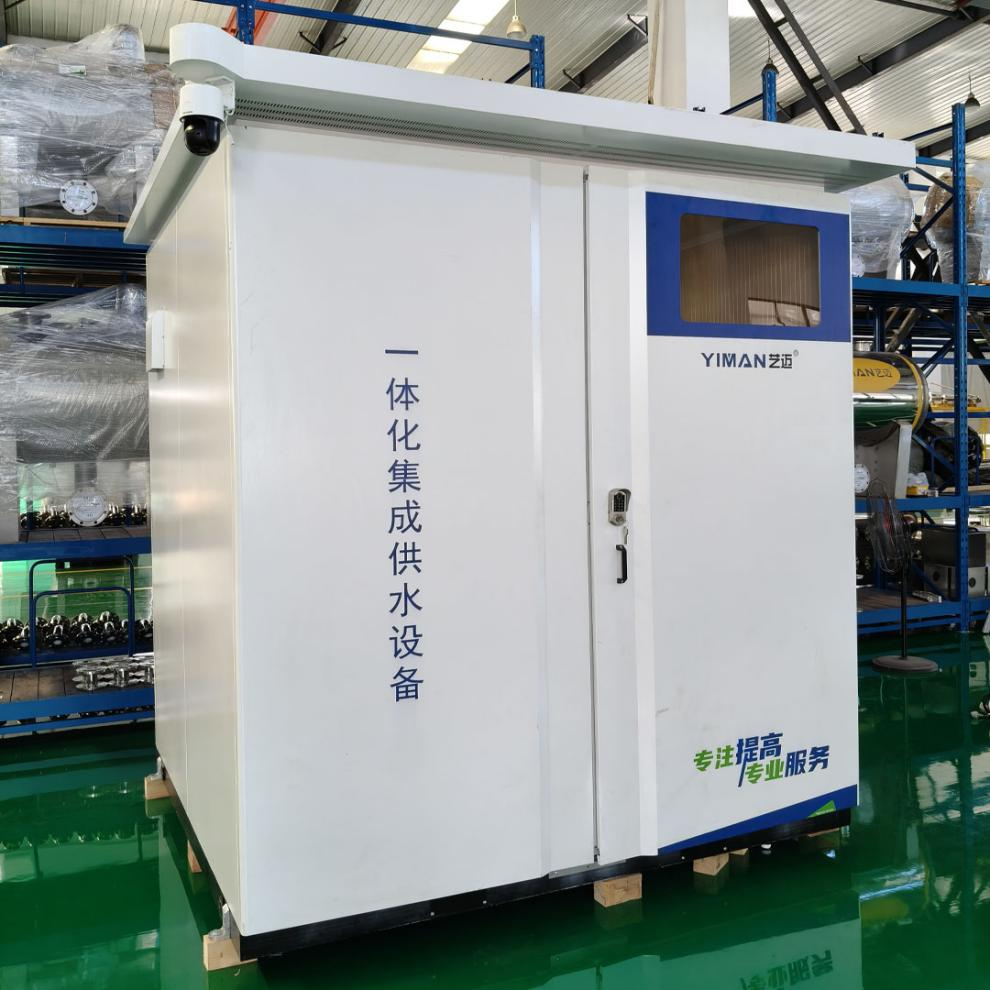

Household Booster Water System: The Mini-Type Solution for Constant Residential Pressure

A consistent, strong water supply is not a luxury; it is a necessity. For many homes and small-scale buildings, low mains pressure and fluctuating flow rates create daily frustration, especially during peak demand times. The solution is no longer a complex, noisy collection of parts installed in a damp basement. We solve this problem with the household booster water system, specifically the mini-type integrated units. These units apply industrial-grade, Frequency-Controlled Constant Pressure Water Supply technology to the residential setting. We deliver a quiet, compact, and energy-saving solution that eliminates water pressure fluctuation and ensures every faucet in your home maintains a steady flow, regardless of how many others are running.

What’s the Challenge of Low Residential Water Pressure?

Low water pressure is caused by several factors, often a combination of them. The most common issues for residential properties include the property’s height relative to the municipal water source or water tank, an undersized meter, or simply high neighborhood demand. When the pressure at the mains is insufficient to push water to the upper floors of an apartment or to handle simultaneous use of multiple fixtures—like a shower and a washing machine—the user experiences a drop in performance.

Traditional water systems often use simple pressure switch pumps that cycle on and off abruptly, causing the water hammer effect and significant pressure variations. This approach wastes energy and subjects the system to unnecessary wear. Our focus is on providing a stable, predictable water supply that mirrors the quality of a centralized system, even in a small-scale building.

Why Mini-type Booster Water Systems Are the Modern Standard?

The Mini-type booster water system integrates the pump, motor, pressure tank, and Variable Frequency Drive (VFD) controller into one compact unit. This “all-in-one” design offers several advantages over legacy systems:

- Space Saving: The integrated unit occupies minimal floor space, making it suitable for tight utility closets or beneath stairs.

- Plug-and-Play Installation: Because all components are pre-piped and wired in the factory, residential water pump installationtime and complexity are drastically reduced. This lowers the total project cost.

- Increased Reliability: Integrating the components ensures they are perfectly matched and protected from external environmental factors. This streamlined approach minimizes potential points of failure.

This integrated approach is core to the “one-stop solution” philosophy we adopt. We engineer the entire system for efficiency and seamless operation, rather than assembling disparate parts.

The Technology Behind Frequency-Controlled Constant Pressure Water Supply

The critical technology within the household booster water system is the VFD controller. This is what differentiates a high-quality system from a basic pressure switch pump.

A VFD constantly monitors the system’s output water pressure in real-time. When a tap is opened, the pressure drops, and the VFD responds not by simply switching the pump on, but by precisely adjusting the motor speed to match the required flow rate.

When demand is low (one faucet running), the motor runs at a low speed, drawing minimal power. When demand is high (multiple fixtures running), the VFD ramps the motor speed up just enough to maintain the pre-set, constant pressure target.

This results in genuine constant pressure water supply without the noticeable pressure surges or dips that plague older systems. Crucially, by running the motor at lower speeds for most of the day, the system significantly reduces energy consumption and extends the life of the pump and motor components.

| Component | Function | Material/Specification Focus (Yimai Standard) |

| Pump | Lifts and pressurizes the water. | Often a vertical multistage pump or self-priming pump, typically using 304 stainless steel parts for corrosion resistance and water quality. |

| Motor | Provides the mechanical power. | High-efficiency motor (such as IE3/IE4 standard) with low vibration to ensure quiet operation. |

| VFD Controller | Monitors pressure and adjusts motor speed. | Uses a high-speed microprocessor to maintain constant pressure within a tight tolerance (e.g., ±0.01 MPa). |

| Pressure Tank | Absorbs minor pressure fluctuations and prevents frequent pump starts. | Small, food-grade diaphragm tank integrated into the unit. |

Key Components of a Reliable Household Booster Water System

We select components that ensure long-term, trouble-free operation. Reliability in a Mini-type booster water system hinges on the quality of three core parts: the pump, the motor, and the control system.

The Pump Material

For any drinking water application, we insist on stainless steel wetted parts. We often use the 304 stainless steel vertical multistage pump model. This material choice is not just about longevity; it prevents corrosion and ensures the water remains clean and free of rust or metallic contamination, surpassing the requirements for basic cast iron pumps.

The Motor

The motor must be designed to work seamlessly with the VFD. A quality motor uses high-grade bearings and construction to handle variable speed operation without overheating or generating excessive vibration. The motor’s insulation class (like F-class) and protection grade (like IP55) ensure it resists moisture and dust, contributing to a longer service life, particularly in non-ideal installation environments.

The Integrated Controller

The control panel must feature user-friendly diagnostics. Modern controllers allow for quick troubleshooting and often offer features like dry-run protection, over-voltage/under-voltage protection, and anti-seize function (periodically running the pump during long periods of inactivity). These protective functions are crucial for minimizing maintenance.

Residential Water Pump Installation: Placement and Setup Considerations

Successful residential water pump installation requires more than just connecting pipes. The location and setup profoundly impact the system’s performance and noise level.

- Air Ventilation and Temperature: All motors generate heat. Ensure the installation area has adequate ventilation to keep the ambient temperature within the motor’s rated limit (typically up to 40 celsius degree. Overheating will reduce motor lifespan.

- Acoustic Isolation: While the quiet Vertical Multistage Pumpis designed for low noise, placing it on a stable, level concrete slab and using anti-vibration rubber pads will further isolate mechanical noise and prevent structure-borne vibration from traveling through the building. Avoid mounting the pump directly onto wooden floors or thin walls.

- Suction Pipe Integrity: The suction side piping must be absolutely airtight. Even small leaks can allow air into the system, leading to noise, reduced performance, and potential cavitation damage. We recommend the shortest possible suction pipe length with minimal bends.

- Accessibility: Position the unit to allow easy access for visual inspection, maintenance, and connection to the power supply.

Maintenance Checklist for Your Quiet Booster Pump

The VFD technology drastically reduces wear and tear, meaning maintenance for a quality Vertical Multistage Centrifugal Pump is minimal. However, we recommend a simple annual check:

- Check Pressure Settings: Verify the actual system pressure aligns with the set constant pressure value on the VFD.

- Inspect Electrical Connections: Shut off power and check all terminal connections for tightness and signs of corrosion. Loose connections generate heat and can cause motor failure.

- Monitor for Leaks: Visually inspect the pump seals and all pipework for drips or signs of moisture. Address any leaks immediately to prevent water damage or system air intrusion.

- Listen for Changes: While the pump is running, listen for any new or unusual noises—such as grinding, rattling, or clicking—which may indicate bearing wear or debris in the pump volute.

By following this simple routine, you ensure the system operates at peak efficiency and avoids premature failure.

Selection Criteria of Household Booster Water System

When selecting a household booster water system, prioritize quality over the lowest price. Look for systems that offer:

- Integrated VFD control: Essential for true constant pressure and energy savings.

- High-Quality Materials: Stainless steel components for water contact.

- Comprehensive Protection: Built-in features like dry-run and anti-seize protection.

- Certification: Ensure the system meets relevant national and international safety and material standards.

Choosing an integrated unit from a specialist means choosing reliability, energy efficiency, and a guaranteed constant water supply for your property.

Toward a New Era of Smart Household Booster Water System

The trend for small-scale water systems is moving rapidly toward deeper integration and predictive maintenance. We see this evolution driven by the demands for both higher energy efficiency and superior reliability. While current Mini-type booster water system units already utilize VFDs, the next generation will heavily incorporate compact Permanent Magnet Synchronous Motors (PMSMs) and advanced communication protocols.

Our expertise, drawn from developing industrial-grade solutions, provides a glimpse into this future. Our industrial IE4 series three-phase asynchronous motor is a standard for high efficiency, featuring an IP55 protection grade and IC411 cooling method. This ruggedness and thermal management, while designed for large industrial pumps, will be miniaturized and integrated into residential units.

We anticipate a shift toward ‘smart integrated systems’ that continuously transmit operational data (flow rate, pressure, energy consumption) via Wi-Fi or Bluetooth. This allows for remote, cloud-based monitoring. Instead of reacting to a pump failure, a system will use algorithms to predict bearing wear or early signs of cavitation hours or days before a catastrophic failure occurs. This approach transforms reactive maintenance into a scheduled, proactive task, drastically improving uptime for both apartment buildings and residential properties.

Shanghai Yimai specializes in manufacturing High-Quality Water Booster Systems that deliver exceptional performance and durability. We go beyond standard models by offering Customized Booster Sets tailored to your project’s specific flow, pressure, and space constraints. This engineering-first approach guarantees a perfectly optimized system for hotels, hospitals, and industrial facilities, ensuring long-term operational reliability and cost savings.

If you have any questions about purchasing household booster water system, feel free to contact us!

- Whatsapp:+86 177 2113 2843

- tony@yimaipump.com

- Shanghai Yimai Industrial Co.Ltd.

466 Jinbai road,Shanghai,China 201506

Frequently Asked Questions (FAQs)

How does a household booster water system ensure constant pressure?

It uses a Variable Frequency Drive (VFD) controller. The VFD continuously monitors the system’s output pressure via a sensor. Instead of simply turning the pump on or off, the VFD adjusts the speed of the motor precisely to match the current water demand. This speed modulation ensures that the system maintains a set pressure value, eliminating the surges and drops you experience with traditional pressure-switch pumps.

What makes a Vertical Multistage Centrifugal Pump quiet, and is it essential?

A Vertical Multistage Pump achieves low noise through two main design features: the VFD operation and high-quality construction. VFD operation avoids the loud, abrupt start-stop cycles of standard pumps, allowing the motor to run smoothly at lower speeds most of the time. Furthermore, using precision-machined components, high-grade motor bearings, and non-vibrating base materials within an integrated enclosure significantly dampens mechanical and hydraulic noise. Quiet operation is essential for maintaining comfort, especially in apartments or homes where the system is located near living spaces.

What is the typical lifespan and energy consumption of a Mini-type booster water system?

A high-quality mini-type pressurization system that uses a VFD and stainless steel components has a typical operational lifespan of 10 to 15 years with proper annual maintenance. In terms of energy consumption, VFD-controlled systems are highly efficient because they adhere to the principle that reducing a motor’s speed by 20% can reduce its energy consumption by almost 50% (the cube law). This technology means the pump only uses the exact amount of power necessary for the current demand, leading to significant long-term energy savings compared to a fixed-speed pump.

Keywords

Household booster water system, mini-type pressurization system, constant pressure water supply, residential water pump installation, quiet booster pump