Unlocking Efficiency: The Benefits of Variable-Speed Booster Pumps

Variable-speed booster pumps offer significant advantages for modern water supply systems. These systems provide consistent water pressure while substantially reducing energy consumption. Understanding their operation helps optimize fluid management across various applications.

Understanding Variable-Speed Booster Pump Technology

Variable-speed booster pumps integrate advanced technology to deliver precise control over water flow and pressure. This differs from traditional fixed-speed pumps, which operate at a constant speed regardless of demand. The core of this technology lies in Variable Frequency Drives (VFDs).

How Variable Frequency Drives Work

A Variable Frequency Drive (VFD) regulates the speed of an electric motor by adjusting the frequency and voltage of its power supply. When water demand is low, the VFD reduces the motor’s speed, decreasing energy usage. Conversely, when demand increases, the VFD accelerates the motor to maintain the desired pressure. This dynamic adjustment ensures that the pump only uses the energy required for current conditions. This leads to substantial energy savings compared to conventional pumps that run at full speed constantly.

Key Components of a VFD Booster System

A typical VFD booster system consists of several integrated components:

- Pumps: Often multiple pumps work in parallel to meet varying demand.

- Variable Frequency Drives (VFDs): These electronic devices control the motor speed.

- Pressure Sensors: These sensors monitor system pressure and provide feedback to the VFDs.

- Controller: An intelligent controller processes data from sensors and manages VFD operations.

- Manifold: Connects pumps and ensures smooth water distribution.

These components work together to create a responsive and efficient water delivery system.

Significant Advantages of Variable-Speed Booster Pumps

The adoption of variable-speed booster pumps brings multiple benefits, enhancing operational efficiency and reducing costs. We have observed these advantages in numerous installations.

Achieving Optimal Energy Efficiency and Cost Savings

Energy efficiency is a primary driver for choosing variable-speed pumps. By matching pump output to actual demand, these systems avoid the wasted energy associated with fixed-speed pumps running at full capacity. Studies indicate energy savings can range from 30% to 60%, leading to significant reductions in electricity bills. For example, a system operating at 80% capacity can save approximately 50% in energy costs compared to a fixed-speed pump. This directly translates into lower operating expenses and a quicker return on investment. If you are interested in reducing energy consumption, consider our article 《Building an Energy-Efficient Water Pumping System》.

| Feature | Variable-Speed Pump | Fixed-Speed Pump | Energy Savings (Approx.) |

|---|---|---|---|

| Energy Consumption | Demand-driven | Constant (High) | 30-60% |

| Pressure Regulation | Consistent | Fluctuating | N/A |

| Equipment Lifespan | Extended | Shorter | N/A |

| Noise Level | Low | High | N/A |

| Operational Cost | Lower | Higher | Significant |

Maintaining Consistent Water Pressure for Enhanced Performance

Variable-speed booster pumps deliver a stable water pressure regardless of fluctuations in demand. This eliminates the common issue of pressure drops when multiple fixtures are in use. For residential buildings, this means consistent showers and reliable appliance operation. In industrial settings, stable pressure is vital for maintaining process integrity and equipment performance. The system actively adjusts to ensure a constant, desired pressure setpoint.

Extending Equipment Lifespan and Reducing Maintenance Needs

The controlled operation of variable-speed pumps reduces mechanical stress on pump components and associated plumbing. Motors start and stop smoothly, minimizing wear and tear. This gentle operation prolongs the lifespan of the pump, motor, and other system parts. Reduced stress also means fewer breakdowns and less frequent maintenance, lowering overall repair costs and operational downtime. This contributes to a more reliable and durable water supply infrastructure.

Minimizing Noise and Vibration in Operation

Traditional pumps often generate considerable noise and vibration due to their constant high-speed operation. Variable-speed pumps, by adjusting their speed according to demand, operate more quietly. This is especially beneficial in residential areas, hospitals, and commercial buildings where noise reduction is critical. The reduced vibration also contributes to the longevity of the entire system.

Applications Where Variable-Speed Booster Pumps Excel

Variable-speed booster pumps are versatile and suitable for a wide range of applications where precise pressure control and energy efficiency are paramount.

Commercial and Residential Water Supply Solutions

In multi-story buildings and large residential complexes, variable-speed pumps ensure all residents receive adequate water pressure, even during peak usage times. They are also ideal for individual homes requiring enhanced water pressure. The consistent pressure improves user comfort and system reliability. For residential applications, consider our article 《Household Booster Water System: The Mini-Type Solution for Constant Residential Pressure》.

Industrial Process Water and HVAC Systems

Industrial processes often require precise water pressure for cooling, cleaning, and manufacturing. VFD Controlled Booster System provide the necessary stability, preventing disruptions and optimizing production. In HVAC systems, they maintain consistent flow rates for heating and cooling, improving system efficiency.

Agricultural Irrigation and Specialized Fluid Handling

Agricultural applications benefit from variable-speed pumps by optimizing water delivery to crops, reducing waste, and saving energy. In specialized fluid handling, where precise flow and pressure are critical, these pumps offer the adaptability needed for various liquids and conditions.

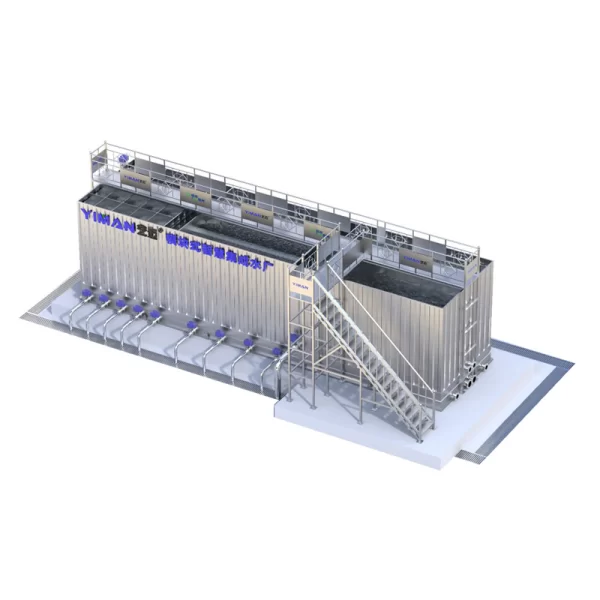

Shanghai Yimai Industrial Co., Ltd.’s Intelligent VFD Booster Solutions

At Shanghai Yimai Industrial Co., Ltd., we specialize in advanced fluid management solutions. Our offerings include intelligent VFD booster systems designed to meet diverse needs while maximizing efficiency and reliability.

Overview of Intelligent Digital Driven VFD Booster Systems

Our Intelligent Digital Driven VFD Booster Systems integrate cutting-edge digital control and VFD technology. These systems feature flow rates from 5 to over 900 m³/h and heads from 15 to 200 meters. They operate with a rated voltage of 380V/220V and a frequency of 50Hz, offering a protection grade of IP65. The maximum overload capacity is 120%, ensuring robust performance. Communication is facilitated via internal CAN and external RS485 methods, allowing for seamless integration into existing infrastructure. These systems are designed for optimal performance and energy savings.

Tailored VFD Controlled Booster Systems for Diverse Needs

Our VFD Controlled Booster Systems are customizable to fit specific application requirements. They feature a flow range of up to 1000 m³/h and a pressure range of up to 2.5 MPa. These systems typically use 2 to 4 pumps, ensuring redundancy and scalability. Pressure adjustment accuracy is within 0.01 MPa, providing precise control. They operate at 380V/50Hz or 60Hz. These systems are ideal for residential water supply, public facilities, commercial buildings, irrigation, and manufacturing plants. We ensure each system is configured for maximum efficiency and longevity.

Discover Your Ideal Water Pressure Solution

Optimizing your water supply system with a variable-speed booster pump can lead to significant energy savings, consistent pressure, and extended equipment life. Contact our experts today to discuss how our intelligent VFD booster solutions can be tailored to your specific needs.

FAQs

What is a variable-speed booster pump?

A variable-speed booster pump is a water pump equipped with a Variable Frequency Drive (VFD) that adjusts the motor speed according to real-time water demand. This dynamic control ensures consistent water pressure and optimizes energy consumption by preventing the pump from running at full capacity unnecessarily.

How much energy can a variable-speed pump save?

Variable-speed pumps can achieve substantial energy savings, typically ranging from 30% to 60% compared to traditional fixed-speed pumps. This is due to their ability to match pump output precisely with demand, significantly reducing electricity usage and lowering operational costs over time.

Are variable-speed pumps suitable for all applications?

Variable-speed pumps are highly versatile and suitable for most applications requiring consistent water pressure and energy efficiency. These include residential buildings, commercial facilities, industrial processes, and agricultural irrigation. However, specific system requirements and flow demands should be evaluated for optimal selection.

What is the typical lifespan of a variable-speed booster pump?

Due to reduced mechanical stress and smoother operation, variable-speed booster pumps generally have an extended lifespan compared to fixed-speed models. The VFD’s ability to minimize starts and stops and operate at lower speeds when demand is low contributes significantly to the longevity of the pump and motor components.

How do variable-speed pumps contribute to system stability?

Variable-speed pumps enhance system stability by maintaining a constant discharge pressure, even with fluctuating water demand. This eliminates pressure drops and surges, ensuring a reliable and steady water supply. This stability is crucial for sensitive industrial processes and comfortable residential use.

Keywords

Keyword: Variable-Speed Booster Pumps, VFD Controlled Booster System, Energy Efficiency, Constant Water Pressure, Fluid Management