Choosing Corrosion-Resistant Pump Materials for Industrial Applications

Industrial pumps operate in diverse and often harsh environments, where corrosive fluids can severely compromise their integrity and performance. We recognize that selecting the appropriate corrosion-resistant materials is paramount for ensuring operational longevity, minimizing downtime, and achieving cost-effectiveness in fluid transfer systems. Understanding the complex interplay between fluid properties, operating conditions, and material science is crucial for making informed decisions in this critical area.

Understanding the Critical Impact of Corrosion on Pump Performance and Longevity

Corrosion poses a significant threat to industrial pumping systems, leading to substantial economic and operational challenges. We must address these issues proactively to maintain system reliability and efficiency.

1. The economic and operational costs of pump corrosion

Corrosion directly impacts an organization’s bottom line through various avenues. Firstly, material degradation necessitates frequent repairs and replacements, increasing maintenance costs. Secondly, unexpected pump failures due to corrosion cause production downtime, resulting in lost output and revenue. Thirdly, compromised pump efficiency due to corrosion-induced surface roughness leads to higher energy consumption. Lastly, environmental contamination from leaks or spills of corrosive fluids can incur hefty fines and reputational damage. These combined factors underscore the critical need for robust corrosion prevention strategies.

2. Common types of corrosion affecting industrial pumps

Industrial pumps are susceptible to several forms of corrosion, each with distinct mechanisms and material vulnerabilities.

- Uniform Corrosion: This type involves an even attack over the entire metal surface, leading to a general thinning of the material. It is predictable but can still cause significant material loss over time.

- Pitting Corrosion: Localized attack creates small holes or “pits” on the metal surface. This form is particularly dangerous because it can lead to rapid perforation even when overall material loss is minimal.

- Crevice Corrosion: Occurs in confined spaces, such as under gaskets or bolt heads, where stagnant fluid allows for localized chemical changes. This creates an aggressive environment that accelerates corrosion.

- Galvanic Corrosion: Happens when two dissimilar metals are in electrical contact within a corrosive electrolyte. The more active metal corrodes preferentially.

- Erosion-Corrosion: A synergistic attack combining mechanical wear from fluid flow or abrasive particles with chemical corrosion. This often occurs in areas of high velocity or turbulence.

- Stress Corrosion Cracking (SCC): A brittle fracture of a normally ductile material when subjected to tensile stress in a specific corrosive environment. This is often unpredictable and can lead to catastrophic failure.

3. Industry standards and regulations for material selection in corrosive environments

Adhering to industry standards and regulations is essential for ensuring the safety, reliability, and compliance of pumping systems in corrosive applications. Organizations like the American Society for Testing and Materials (ASTM), the National Association of Corrosion Engineers (NACE), and the International Organization for Standardization (ISO) provide guidelines for material selection, testing, and performance in corrosive media. These standards specify acceptable corrosion rates, material compositions, and manufacturing practices. Compliance helps mitigate risks, ensures interoperability, and provides a framework for quality assurance. Engineers must consult relevant standards, such as NACE MR0175 for sour service environments, to make informed material choices.

Key Factors Influencing Material Selection for Corrosion-Resistant Pumps

Effective material selection for corrosion-resistant pumps requires a comprehensive understanding of the operating environment. We must analyze several critical factors to ensure optimal performance and longevity.

1. Analyzing the properties of the pumped fluid: pH, temperature, and chemical composition

The characteristics of the fluid being pumped are the primary determinants for material selection.

- pH: The acidity or alkalinity of the fluid significantly influences corrosion rates. Highly acidic (low pH) or highly alkaline (high pH) solutions require materials with excellent resistance to chemical attack. For example, strong acids often necessitate specialized alloys or non-metallic liners.

- Temperature: Elevated fluid temperatures generally accelerate chemical reactions and corrosion rates. A material that performs well at ambient temperatures might rapidly degrade under higher thermal conditions. We must consider both continuous operating temperatures and potential temperature excursions. For applications involving high-temperature fluids like thermal oil, the Heat Conducting Oil Pump is designed with superior heat-resistant materials.

- Chemical Composition: The specific chemical compounds present in the fluid dictate the type and severity of corrosive attack. Oxidizing agents, chlorides, sulfides, and other aggressive species demand materials with specific chemical resistances. A detailed chemical analysis of the fluid is indispensable for accurate material specification.

2. Evaluating operational conditions: pressure, flow rate, and abrasive particles

Beyond fluid properties, the mechanical and physical conditions of pump operation also play a crucial role in material durability.

- Pressure: High system pressures can increase the driving force for corrosive reactions and may necessitate materials with higher mechanical strength and resistance to stress corrosion cracking.

- Flow Rate: High fluid velocities can lead to erosion-corrosion, where the mechanical removal of passive films accelerates chemical attack. Conversely, very low flow rates can promote crevice corrosion due to stagnant conditions.

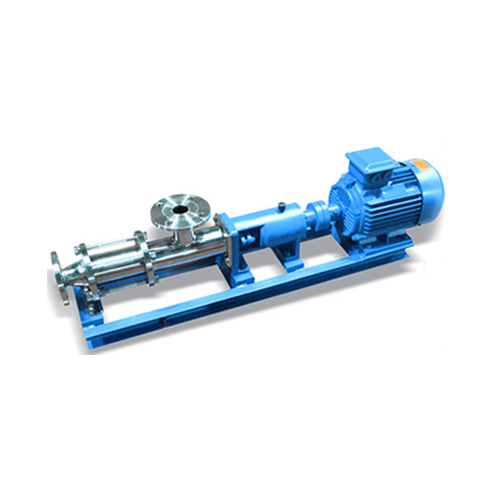

- Abrasive Particles: The presence of solid particles in the fluid can cause abrasive wear, which, when combined with corrosive media, significantly exacerbates material degradation. Materials chosen for such applications must possess both corrosion and abrasion resistance. For instance, Stainless steel single screw pump are often used for fluids that contain some solid particles, requiring robust material choices.

3. Considering environmental factors: ambient temperature and atmospheric corrosivity

The external environment surrounding the pump also influences material selection.

- Ambient Temperature: Extreme ambient temperatures can affect the mechanical properties of pump materials and influence the rate of atmospheric corrosion on external surfaces.

- Atmospheric Corrosivity: Pumps operating in marine environments, chemical plants, or areas with high humidity or industrial pollutants are exposed to corrosive atmospheres. External pump components must also be selected for resistance to these conditions to prevent external degradation and maintain structural integrity.

A Comprehensive Guide to Corrosion-Resistant Pump Materials and Their Applications

Choosing the right material is a complex decision that balances chemical resistance, mechanical properties, cost, and availability. We examine various material categories for industrial pumps.

1. Stainless steels (SS304, SS316, SS316L) for various corrosive media

Stainless steels are widely used due to their versatility and cost-effectiveness. Their corrosion resistance stems from a passive chromium oxide layer that forms on the surface.

- SS304: This austenitic stainless steel offers good corrosion resistance to many chemical corrodents and is suitable for mild to moderately corrosive environments. It is commonly used in water treatment, food processing, and general industrial applications. However, it is susceptible to pitting and crevice corrosion in chloride-rich environments.

- SS316: Containing molybdenum, SS316 provides enhanced resistance to pitting and crevice corrosion, particularly in chloride-containing media. It is a preferred choice for marine applications, chemical processing, and pharmaceutical industries where SS304 might fail.

- SS316L: The “L” denotes low carbon content, which improves weldability and reduces the risk of sensitization (carbide precipitation) during welding. This makes SS316L ideal for welded components in corrosive service, preventing intergranular corrosion. Shanghai Yimai Industrial Co., Ltd. utilizes SS304 and SS316L for components in our Vertical Multi-Stage Centrifugal Pump and Single stage end suction volute pump, demonstrating our commitment to durability.

| Material Type | Primary Alloying Elements | Key Corrosion Resistance | Typical Applications | Limitations |

|---|---|---|---|---|

| SS304 | Cr, Ni | General corrosion | Water, food, mild chemicals | Chlorides, strong acids |

| SS316 | Cr, Ni, Mo | Pitting, crevice corrosion | Marine, chemicals, pharmaceuticals | Strong acids, very high chlorides |

| SS316L | Cr, Ni, Mo (low C) | Pitting, crevice, intergranular corrosion | Welded structures, aggressive chemicals | Similar to SS316 but improved weldability |

| Hastelloy | Ni, Mo, Cr | Broad-spectrum chemical resistance | Extreme acids, high temperatures | High cost |

| Titanium | Ti | Oxidizing acids, chlorides | Seawater, chlorine, nitric acid | Non-oxidizing acids, high temperatures |

| Duplex SS | Cr, Ni, Mo, N | High strength, SCC resistance | Oil & gas, desalination | High temperatures |

2. Specialized alloys: Hastelloy, Titanium, and Duplex Stainless Steel for extreme conditions

For highly aggressive or extreme operating conditions, specialized alloys become necessary.

- Hastelloy: This family of nickel-chromium-molybdenum alloys offers exceptional resistance to a wide range of corrosive media, including strong acids, oxidizing and reducing agents, and high temperatures. Hastelloy C-276, for example, is renowned for its resistance to pitting, crevice corrosion, and stress corrosion cracking. It is often employed in chemical processing, pollution control, and nuclear industries.

- Titanium: Known for its outstanding corrosion resistance, particularly in oxidizing environments and chloride solutions like seawater, titanium forms a tenacious passive oxide layer. It is lightweight and strong, making it suitable for aerospace, marine, and chemical processing applications involving chlorine, nitric acid, and various salts. However, it performs poorly in non-oxidizing acids.

- Duplex Stainless Steel: These alloys combine austenitic and ferritic microstructures, offering a superior balance of strength and corrosion resistance compared to conventional stainless steels. Duplex stainless steels exhibit excellent resistance to stress corrosion cracking and pitting in chloride environments, making them ideal for oil and gas, desalination, and pulp and paper industries.

3. Non-metallic options: Plastics, ceramics, and rubber linings for specific chemical resistance

In certain applications, non-metallic materials provide superior corrosion resistance, especially against highly reactive chemicals.

- Plastics: Materials like Polyvinyl Chloride (PVC), Polypropylene (PP), and Polyvinylidene Fluoride (PVDF) are excellent choices for handling aggressive acids, bases, and solvents at moderate temperatures. Their inertness makes them suitable for chemical dosing, water treatment, and laboratory applications. However, they have lower mechanical strength and temperature limits compared to metals.

- Ceramics: Silicon carbide and alumina ceramics offer exceptional hardness, abrasion resistance, and chemical inertness, even at high temperatures. They are used in highly abrasive and corrosive slurries, and for pump components like mechanical seals and bearings. Their brittleness is a primary limitation.

- Rubber Linings: Natural and synthetic rubbers (e.g., EPDM, Neoprene, Butyl) are often used as linings for pump casings and impellers. They provide excellent resistance to abrasion and certain chemicals, absorbing impact and preventing direct contact between the fluid and the metallic pump body. This approach is effective for slurry pumps and specific chemical services.

4. Shanghai Yimai Industrial Co., Ltd.’s material offerings for diverse pump types

At Shanghai Yimai Industrial Co., Ltd., we prioritize material selection to ensure the reliability and longevity of our products. Our Vertical Multi-Stage Centrifugal Pump and Single stage end suction volute pump models are available with pump casing, impeller, and shaft materials in Cast Iron, SS304, and SS316L, among others. This range allows us to cater to diverse fluid properties and operational demands, from clean water applications to moderately corrosive industrial processes. Our Stainless steel single screw pump also features SUS304 and SUS316 materials, specifically chosen for their resistance to various media and suitability for applications involving viscous or abrasive fluids. By offering these robust material options, we empower our clients to specify pumps that precisely match their corrosive environments, minimizing maintenance and maximizing operational uptime.

Best Practices for Specifying and Maintaining Corrosion-Resistant Pump Systems

Optimizing the lifespan and performance of corrosion-resistant pump systems involves careful design, diligent maintenance, and expert consultation. These practices collectively minimize the impact of corrosive environments.

1. Implementing proper design considerations for enhanced corrosion resistance

Effective design is the first line of defense against corrosion.

- Material Compatibility Assessment: Conduct thorough compatibility studies between the pumped fluid and all wetted pump components, including casing, impeller, shaft, and seals.

- Avoidance of Galvanic Couples: Design the system to prevent direct electrical contact between dissimilar metals in the presence of an electrolyte. If unavoidable, use electrical isolation or ensure the anodic material has a large surface area.

- Minimizing Crevices: Design components to eliminate or minimize stagnant areas where crevice corrosion can initiate. This involves smooth finishes and proper gasket design.

- Optimizing Flow Paths: Design pump internals to ensure smooth fluid flow, reducing turbulence and high-velocity zones that can lead to erosion-corrosion.

- Drainage and Venting: Incorporate proper drainage and venting to prevent stagnant fluid accumulation during shutdown, which can accelerate corrosion.

- Accessibility for Inspection: Ensure critical components are accessible for regular inspection and maintenance, allowing early detection of corrosion.

For more insights into pump selection, consider reading Picking the Right Water Pump: A Step-by-Step Selection Guide.

2. Regular inspection and maintenance strategies to prolong pump life

Proactive maintenance is crucial for extending the operational life of corrosion-resistant pumps.

- Scheduled Visual Inspections: Regularly inspect pump exteriors and accessible internal components for signs of corrosion, pitting, or wear.

- Performance Monitoring: Track pump performance parameters (flow, pressure, power consumption) to identify deviations that may indicate internal corrosion or degradation.

- Fluid Analysis: Periodically analyze the pumped fluid to detect changes in chemical composition, pH, or corrosive agents that could accelerate material degradation.

- Seal and Gasket Replacement: Replace seals and gaskets according to manufacturer recommendations or at the first sign of leakage, as these are common areas for crevice corrosion.

- Cleaning and Flushing: Implement regular cleaning and flushing procedures, especially during shutdowns, to remove corrosive residues or deposits.

- Documentation: Maintain detailed records of inspections, repairs, and material replacements to track pump history and inform future maintenance decisions.

3. The role of protective coatings and linings in mitigating corrosion

Protective coatings and linings offer an additional layer of defense against corrosion, especially for less resistant base materials or in specific areas of high attack.

- Coatings: Applied to metallic surfaces, coatings like epoxy, ceramic, or fluoropolymer provide a barrier between the metal and the corrosive fluid. They are effective against various chemicals and can extend the life of components. Proper surface preparation is critical for coating adhesion and effectiveness.

- Linings: Thicker and often more robust than coatings, linings (e.g., rubber, plastic, glass) are typically bonded to the internal surfaces of pump casings. They offer excellent chemical resistance and can also provide abrasion resistance. Linings are particularly useful for highly corrosive or abrasive slurries, protecting the structural integrity of the pump.

4. Consulting with experts for optimal material selection and system design

Given the complexities of corrosion and material science, consulting with experienced professionals is invaluable. Corrosion engineers and pump specialists can provide expert guidance on:

- Detailed Fluid Analysis: Interpreting complex fluid compositions and predicting their corrosive potential.

- Material Specification: Recommending the most suitable and cost-effective materials based on specific application parameters.

- Design Optimization: Advising on pump design modifications to enhance corrosion resistance and prevent common failure modes.

- Failure Analysis: Investigating pump failures to identify root causes related to corrosion and recommend corrective actions.

- Maintenance Program Development: Establishing effective inspection and maintenance schedules tailored to the corrosive environment.

For further information on optimizing industrial heating systems, you may find Optimizing Industrial Heating: A Deep Dive into the Heat Conduction Oil Pump insightful.

Partnering for Pump System Integrity

Selecting the appropriate corrosion-resistant pump materials is a critical decision that directly impacts operational efficiency, safety, and long-term costs. At Shanghai Yimai Industrial Co., Ltd., we combine extensive expertise with a diverse product portfolio to help you navigate these complex choices. Our range of pumps, featuring robust materials like Cast Iron, SS304, and SS316L, is engineered for durability in challenging industrial environments. We are committed to providing solutions that ensure your fluid transfer systems operate reliably and efficiently, minimizing downtime and maximizing your investment. For expert advice on optimizing your pump systems or to discuss your specific material requirements, please contact us.

Email: tony@yimaipump.com

Phone/WhatsApp: +86 134 8229 5009

FAQs

1. What are the most common types of corrosion found in industrial pumps?

Industrial pumps frequently experience uniform corrosion, pitting corrosion, crevice corrosion, and erosion-corrosion. These types account for a significant portion of pump failures in corrosive environments. Understanding these mechanisms helps in selecting appropriate materials and implementing preventative measures.

2. How does fluid temperature affect the choice of pump material?

Fluid temperature significantly influences corrosion rates; higher temperatures generally accelerate chemical reactions and material degradation. A material suitable for ambient conditions may rapidly corrode at elevated temperatures. Therefore, engineers must select materials with proven resistance at the maximum operating temperature.

3. Can a single material be universally corrosion-resistant for all applications?

No, no single material offers universal corrosion resistance across all industrial applications. The optimal material depends on specific factors like fluid chemistry, temperature, pressure, and the presence of abrasives. Each material has unique strengths and weaknesses against different corrosive agents.

4. What is the significance of ‘L’ in SS316L stainless steel?

The ‘L’ in SS316L denotes a low carbon content. This low carbon variant significantly improves weldability by reducing the risk of sensitization, which is the formation of chromium carbides during welding. Sensitization can lead to intergranular corrosion in corrosive environments, making SS316L a better choice for welded components.

5. How often should corrosion-resistant pumps be inspected?

The inspection frequency for corrosion-resistant pumps depends on the severity of the corrosive environment, the criticality of the application, and regulatory requirements. Typically, visual inspections should occur quarterly, with more detailed internal inspections and performance monitoring conducted annually or semi-annually. High-risk applications may require more frequent checks.