Choosing Corrosion-Resistant Pump Materials for Optimal Performance

Selecting appropriate pump materials is crucial for ensuring long-term operational reliability and cost-effectiveness in industrial applications. We understand that corrosion can severely compromise pump integrity, leading to premature failure, increased maintenance, and costly downtime. Our goal is to provide comprehensive guidance on how to identify the right materials that withstand aggressive environments, thereby extending equipment lifespan and optimizing system performance.

Understanding the Impact of Corrosion on Pump Systems

Pumps are indispensable components across a multitude of industrial sectors, facilitating the movement of various fluids. Their continuous operation is vital for processes ranging from chemical manufacturing to wastewater treatment. When corrosion attacks pump components, it compromises their structural integrity and functional efficiency.

The critical role of pumps in industrial processes

Pumps serve as the heart of many industrial operations, circulating essential fluids like water, chemicals, oils, and slurries. Their reliable performance directly impacts production rates, product quality, and overall system safety. Any failure in a pumping system can trigger a cascade of operational disruptions and significant financial losses.

Common types of corrosion affecting pump components

Several types of corrosion threaten pump components, each with distinct mechanisms and material vulnerabilities. Understanding these forms is key to effective material selection.

- Uniform Corrosion: This type of corrosion occurs evenly over the entire exposed surface of the material. It is predictable but can lead to significant material loss if not addressed.

- Pitting Corrosion: This localized form of corrosion creates small holes or “pits” on the metal surface. It is particularly dangerous because it can cause rapid penetration and failure with minimal overall material loss.

- Crevice Corrosion: This occurs in confined spaces where oxygen access is restricted, such as under gaskets or bolt heads. It is common in stagnant solutions and can be very aggressive.

- Galvanic Corrosion: This happens when two dissimilar metals are in electrical contact within a corrosive electrolyte. The more active metal corrodes preferentially.

- Erosion-Corrosion: This is a synergistic attack involving both mechanical wear (erosion) and chemical corrosion. High fluid velocities and abrasive particles often exacerbate this type of damage.

- Stress Corrosion Cracking (SCC): This involves the initiation and growth of cracks due to the combined effects of tensile stress and a corrosive environment. It can lead to sudden and catastrophic failures.

The financial and operational consequences of pump corrosion

The impact of pump corrosion extends far beyond the immediate damage to the equipment. Financially, it results in increased repair and replacement costs, higher inventory for spare parts, and elevated labor expenses for maintenance. Operationally, corrosion causes unplanned downtime, reduced production capacity, safety hazards, and potential environmental contamination. These consequences underscore the necessity of proactive material selection.

Key factors influencing corrosion rates in pump environments

Various environmental and operational factors dictate the rate and type of corrosion a pump experiences. Engineers must carefully consider these variables during the design and selection phases.

- Fluid Chemistry: The chemical composition of the pumped media, including pH, concentration of corrosive agents (e.g., acids, bases, chlorides), and dissolved gases (e.g., oxygen, CO2, H2S), profoundly influences corrosion.

- Temperature: Elevated temperatures generally accelerate chemical reactions, thereby increasing corrosion rates. Some materials also lose their protective properties at higher temperatures.

- Pressure: High pressures can affect the solubility of gases and the stability of protective films, potentially influencing corrosion.

- Velocity and Flow Regime: High fluid velocities can cause erosion-corrosion, especially with abrasive fluids. Stagnant zones, conversely, can promote crevice corrosion.

- Abrasive Particles: Suspended solids in the fluid can mechanically wear down protective layers and expose fresh metal surfaces to corrosive attack.

- Presence of Oxygen: Oxygen is a primary driver for many corrosion processes, particularly in aqueous environments.

- Microbiological Influenced Corrosion (MIC): Certain microorganisms can accelerate corrosion by creating localized corrosive conditions or altering the chemistry of the fluid.

Essential Material Properties for Corrosion Resistance in Pumps

Selecting the right material requires a deep understanding of its inherent properties and how it interacts with specific operating conditions. We prioritize materials that offer robust resistance to the identified corrosive agents.

An overview of metallic materials and their corrosion characteristics

Metallic materials form the backbone of most pump constructions, offering strength and durability. However, their corrosion resistance varies widely.

- Carbon Steel: Economical and strong, but highly susceptible to corrosion in most aqueous and acidic environments. It is often used for non-corrosive or mildly corrosive applications.

- Cast Iron: Offers good wear resistance and is cost-effective. It performs well in neutral or alkaline solutions but corrodes in acidic environments. Split casing double suction pump and Single stage end suction volute pump often utilize cast iron for their casings.

- Stainless Steels: These alloys contain a minimum of 10.5% chromium, which forms a passive, protective oxide layer. This layer provides excellent corrosion resistance in many environments.

- Nickel Alloys: Offer superior corrosion resistance to stainless steels in highly aggressive environments, especially those involving chlorides, acids, and high temperatures.

- Titanium: Known for exceptional corrosion resistance, particularly in oxidizing acids, chlorides, and seawater. It is lightweight but expensive.

The benefits and limitations of stainless steels (e.g., SS304, SS316L) in corrosive applications

Stainless steels are widely used due to their balance of corrosion resistance, mechanical properties, and cost.

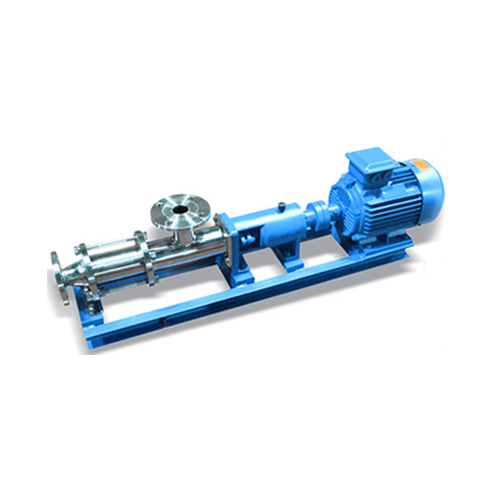

- SS304 (18% Chromium, 8% Nickel): Offers good general corrosion resistance in many environments, including fresh water and mild chemicals. It is susceptible to pitting and crevice corrosion in chloride-rich solutions. Our Vertical Multi-Stage Centrifugal Pump and Stainless steel single screw pump often feature SS304 for its versatility.

- SS316L (16% Chromium, 10% Nickel, 2% Molybdenum): The addition of molybdenum significantly enhances resistance to pitting and crevice corrosion, especially in chloride environments. It is a preferred choice for more aggressive applications than SS304.

However, even stainless steels have limitations. They can suffer from stress corrosion cracking in specific chloride and high-temperature conditions. They are also not immune to all forms of corrosion, particularly in highly reducing or extremely acidic environments.

Exploring the use of cast iron and ductile iron in specific pumping conditions

Cast iron and ductile iron remain viable options for many pump applications where cost and moderate corrosion resistance are critical.

- Cast Iron: Provides good resistance to neutral and alkaline solutions, making it suitable for water and wastewater applications. It also offers excellent machinability and vibration dampening.

- Ductile Iron: Modified cast iron with improved strength and ductility due to the addition of magnesium. It shares similar corrosion resistance to cast iron but offers better impact resistance and can withstand higher pressures.

Both cast iron and ductile iron are typically used for less corrosive fluids, such as clean water or low-corrosive industrial liquids. For instance, our Split casing double suction pump and Single stage end suction volute pump models frequently use cast iron for their pump casings and impellers, proving effective in low-viscosity, non-particle media.

Advanced alloys and non-metallic materials for extreme corrosive environments

For the most aggressive and challenging applications, advanced alloys and non-metallic materials become essential.

- High-Nickel Alloys (e.g., Hastelloy, Inconel): These alloys provide exceptional resistance to a wide range of acids, alkalis, and high-temperature corrosive media. They are often specified for chemical processing and petrochemical industries.

- Reactive Metals (e.g., Titanium, Zirconium, Tantalum): Offer unparalleled corrosion resistance in specific highly aggressive environments. Titanium, for example, excels in oxidizing chloride solutions.

- Non-Metallic Materials (e.g., Plastics, Ceramics, Composites): Materials like PTFE, PVDF, and FRP offer complete immunity to many corrosive chemicals. They are lightweight and do not suffer from electrochemical corrosion. However, they typically have lower mechanical strength and temperature limits than metals.

These materials are typically selected when conventional metals fail to provide adequate protection, justifying their higher cost due to extended service life and enhanced safety.

A Step-by-Step Guide to Selecting the Right Pump Material

Effective material selection is a systematic process that minimizes risks and optimizes long-term performance. We follow a detailed procedure to ensure the best fit for each application.

1. Analyzing the chemical composition and temperature of the pumped media

Begin by thoroughly characterizing the fluid to be pumped, including all chemical constituents and their concentrations. Understand the operating temperature range, as this significantly influences material degradation rates. For example, a Heat Conducting Oil Pump requires materials capable of withstanding high temperatures up to 350°C with low-corrosive media.

2. Evaluating the pH, abrasive particles, and velocity of the fluid

Determine the fluid’s pH, which indicates its acidity or alkalinity. Identify the presence and concentration of any abrasive solids, as these can lead to erosion. Measure or calculate the fluid velocity within the pump, as high velocities can accelerate erosion-corrosion.

3. Considering operating pressure, temperature fluctuations, and environmental factors

Account for the maximum and minimum operating pressures, which affect mechanical stress on components. Assess temperature fluctuations, as thermal cycling can induce stress and fatigue. Consider external environmental factors like ambient temperature, humidity, and exposure to corrosive fumes.

4. Consulting material compatibility charts and industry standards

Refer to established material compatibility charts and industry standards (e.g., NACE, ASTM) to identify suitable materials for the specific fluid and operating conditions. These resources provide empirical data and guidelines for material performance.

5. Balancing performance requirements with cost-effectiveness and availability

Evaluate the technical requirements against the overall project budget and material availability. Sometimes, a slightly less resistant but more cost-effective and readily available material, coupled with robust maintenance, can be the optimal choice.

| Material Type | Common Applications | Corrosion Resistance (General) | Cost (Relative) |

|---|---|---|---|

| Cast Iron | Water, wastewater, neutral solutions | Moderate | Low |

| SS304 | Fresh water, mild chemicals, food processing | Good | Medium |

| SS316L | Chlorides, moderate acids, marine environments | Very Good | Medium-High |

| Duplex Stainless Steel | High chlorides, sour gas, seawater | Excellent | High |

| Hastelloy | Strong acids, high temperatures, aggressive chemical processes | Superior | Very High |

| PTFE/PVDF | Highly corrosive chemicals, pharmaceuticals | Excellent (chemical inertness) | High |

Shanghai Yimai Industrial’s Expertise in Corrosion-Resistant Pump Solutions

At Shanghai Yimai Industrial Co., Ltd., we leverage extensive experience and technical knowledge to provide pumps engineered for durability in challenging environments. Our commitment to material science ensures optimal performance and longevity for our diverse product range.

How Shanghai Yimai Industrial designs pumps with material selection in mind

We integrate material selection into the core of our pump design process. Our engineers meticulously analyze application data, including fluid properties, operating temperatures, and pressures, to specify the most suitable materials. This proactive approach prevents premature failures and maximizes operational uptime. We also consider the entire pump system, including ancillary components, to ensure comprehensive corrosion protection.

Examples of corrosion-resistant materials used in Yimai pumps (e.g., SS304/SS316L in Vertical Multi-Stage Centrifugal Pumps and Single Screw Pumps)

Many of our pumps feature robust, corrosion-resistant materials. For instance, our Vertical Multi-Stage Centrifugal Pump models are frequently constructed with SS304 or SS316L for pump casings, impellers, and shafts, making them ideal for clean water, process water systems, and even acid and alkali handling. Similarly, our Stainless steel single screw pump utilizes SUS304 and SUS316, ensuring reliable performance when handling various viscous and corrosive media. These material choices reflect our dedication to quality and application-specific solutions.

Addressing specific application challenges with tailored material choices for Yimai’s diverse product range

Our broad product portfolio, including Heat Conducting Oil Pump, Split casing double suction pump, and Single stage end suction volute pump, allows us to address a wide array of industrial demands. For high-temperature applications, our Heat Conducting Oil Pumps are built with specialized heat-resistant alloys. For applications involving abrasive or corrosive slurries, we can recommend pumps with hardened materials or non-metallic liners. We tailor material specifications to meet the unique challenges of each client’s operational environment, ensuring long-term reliability.

The importance of mechanical seals and their material compatibility for leak prevention

Mechanical seals are critical components for preventing fluid leakage and maintaining pump efficiency. Their materials must be compatible with both the pumped fluid and the pump casing to avoid galvanic corrosion and chemical degradation. We pay close attention to selecting appropriate seal faces (e.g., silicon carbide, tungsten carbide) and elastomers (e.g., Viton, EPDM) that can withstand the specific chemical and thermal conditions of the application. This ensures leak-free operation and extends the lifespan of the entire pump system.

Best Practices for Maintaining and Extending Pump Lifespan in Corrosive Environments

Even with optimal material selection, proper maintenance is essential to combat corrosion and maximize pump lifespan. Implementing a comprehensive maintenance strategy can significantly reduce operational costs and improve reliability.

Implementing regular inspection and preventative maintenance schedules

Establish and adhere to a strict schedule for inspecting pump components, looking for early signs of corrosion, wear, or damage. Regular preventative maintenance, including lubrication, seal checks, and component replacement, can preempt major failures. Document all inspections and maintenance activities to track performance and identify trends.

Understanding the role of protective coatings and linings

In certain applications, protective coatings and linings can augment the corrosion resistance of pump materials. These can include epoxy coatings, rubber linings, or ceramic composites, which create a barrier between the fluid and the pump’s metallic surfaces. Select coatings based on chemical compatibility and abrasion resistance.

Proper storage and handling of pumps and components

Ensure that spare pumps and components are stored in a dry, controlled environment to prevent atmospheric corrosion. Follow manufacturer guidelines for handling to avoid mechanical damage that could compromise protective layers. Proper preservation techniques, such as applying rust inhibitors, are also vital.

Training personnel on corrosion awareness and material handling

Educate maintenance and operational staff on the different types of corrosion, their causes, and the specific materials used in their pumps. Training should cover proper handling procedures for corrosive fluids and the importance of adhering to material compatibility guidelines during repairs and replacements. This knowledge empowers staff to make informed decisions that protect pump assets.

Request a Consultation

Ensuring the longevity and efficiency of your pumping systems in corrosive environments requires expert material selection and robust engineering. Partner with Shanghai Yimai Industrial Co., Ltd. to benefit from our specialized knowledge and high-quality solutions. Our team is ready to analyze your specific application needs and recommend the optimal corrosion-resistant pump materials and designs.

Contact us today to discuss your project requirements.

Email: tony@yimaipump.com

Phone/WhatsApp: +86 134 8229 5009

FAQs

1. What are the most common types of corrosion that affect industrial pumps?

Industrial pumps commonly experience uniform corrosion, pitting corrosion, crevice corrosion, galvanic corrosion, and erosion-corrosion. Each type results from different environmental interactions and material vulnerabilities, demanding specific preventative measures and material choices. Understanding these forms is critical for effective pump maintenance and selection.

2. How do temperature and chemical concentration impact material selection for pumps?

Temperature and chemical concentration significantly influence corrosion rates. Higher temperatures generally accelerate chemical reactions, increasing material degradation. Similarly, higher concentrations of corrosive chemicals intensify the attack on pump materials. Therefore, material selection must account for the full range of operating temperatures and chemical concentrations to ensure adequate resistance.

3. When should I consider using exotic alloys or non-metallic materials for my pump?

Consider exotic alloys (e.g., Hastelloy, Titanium) or non-metallic materials (e.g., PTFE, FRP) when standard stainless steels or cast irons fail to provide sufficient corrosion resistance. This is typically necessary in extremely aggressive chemical environments, high-temperature applications, or when dealing with highly concentrated acids, strong alkalis, or specific chloride solutions where conventional materials would rapidly degrade.

4. What specific materials does Shanghai Yimai Industrial Co., Ltd. recommend for highly corrosive applications?

For highly corrosive applications, Shanghai Yimai Industrial Co., Ltd. often recommends advanced stainless steels like SS316L, duplex stainless steels, or specialized alloys such as Hastelloy, depending on the specific chemical environment. For extreme chemical inertness, we may suggest non-metallic options like PVDF or PTFE-lined pumps. Our recommendations are always tailored to the precise fluid characteristics and operating conditions.

5. How can I ensure the mechanical seal material is compatible with my chosen pump casing material?

To ensure mechanical seal compatibility, you must consider the chemical composition and temperature of the pumped fluid, as well as potential galvanic reactions between seal components and the pump casing. Consult material compatibility charts for seal faces (e.g., carbon, silicon carbide) and elastomers (e.g., Viton, Kalrez). Proper selection prevents premature seal failure and maintains leak-free operation.

About the Author

The author is a Senior SEO Content Strategist at Shanghai Yimai Industrial Co., Ltd., specializing in industrial pumping solutions and fluid management technologies. With extensive experience in material science and engineering applications, they provide expert insights into optimizing pump performance and longevity in diverse industrial environments. Their work focuses on delivering practical, data-driven information to engineers, maintenance managers, and procurement specialists.