Optimizing Dewatering: How Screw Design Impacts Performance and Efficiency

Choosing the right screw press for dewatering starts with a clear grasp of how the machine is built. We see, again and again, that the screw’s geometry and material set the tone for separation efficiency, cake dryness, and service life. When the screw is matched to the job, energy use drops and maintenance eases. That simple truth shapes how we push for maximum performance across varied industrial applications.

Understanding the Fundamentals of Screw Press Dewatering Technology for Enhanced Solid-Liquid Separation

Screw presses carry a heavy load in solid-liquid separation across many industries. They dewater sludge to cut volume and make downstream handling or disposal more manageable. The mechanism is straightforward mechanical compression that drives liquid away from solids, yielding a dewatered cake and a filtrate stream. We have observed that thoughtful optimization at this stage can noticeably improve overall efficiency and support environmental compliance.

1. The Principle of Operation: How Screw Presses Achieve Efficient Sludge Dewatering

A screw press feeds sludge continuously into a dewatering zone that narrows as material advances. Inside, a rotating screw shaft with flights applies rising pressure to the sludge. Water is pushed through a screen or filter medium while solids are retained. The compacted solids, or cake, discharge at the end of the screw. This steady mechanical action delivers consistent, effective dewatering.

2. Key Components of a Screw Press and Their Initial Design Considerations

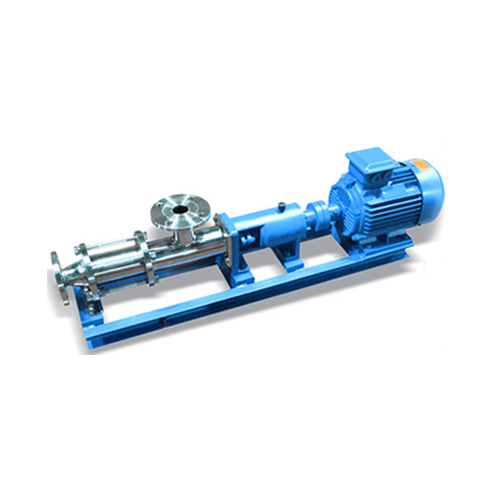

Core elements include the screw shaft, helical flights, and the surrounding casing or screen. The shaft drives rotation and provides structural support. The flights convey and compress the sludge. The casing, often a wedge wire screen, lets filtrate escape while keeping solids in place. Early design choices center on material durability and corrosion resistance, along with tight manufacturing tolerances for reliable performance. Our robust Double Helix Continuous Presser machines exemplify these considerations.

Exploring the Critical Influence of Screw Geometry on Dewatering Efficiency and Cake Dryness

Screw geometry sits at the heart of dewatering results. Small tweaks can swing efficiency, throughput, and final cake dryness by a wide margin. Our engineering team tracks these variables closely to deliver consistent performance gains.

1. The Role of Screw Pitch and Taper in Compression and Liquid Expulsion

Screw pitch, the distance between adjacent flights, governs the compression ratio. A pitch that decreases along the screw shortens available volume for the sludge, building pressure and pushing more liquid out. A tapered shaft, with diameter increasing toward the discharge end, amplifies this compression. Working together, these features drive efficient liquid expulsion and yield a drier cake.

2. How Screw Diameter and Flight Thickness Affect Throughput and Sludge Retention Time

Screw diameter ties directly to volumetric capacity and therefore throughput. Larger diameters generally support higher processing rates. Flight thickness influences the screw’s stiffness and the clearance between flights and casing. The right thickness sustains smooth conveyance and compression without undue wear or clogging. Retention time, shaped by screw speed and length, remains vital for adequate dewatering.

Analyzing the Impact of Screw Material and Surface Treatment on Durability and Maintenance Requirements

Material and surface treatment choices determine how a screw stands up to abrasive, corrosive duty and how often it needs attention. We prioritize options that endure harsh conditions with minimal intervention.

1. Selecting Optimal Materials for Abrasive Sludges: Enhancing Screw Lifespan and Reducing Wear

Abrasive sludges can erode critical components, driving up costs and downtime. Stainless steel grades such as SUS304 and SUS316 provide strong corrosion resistance, while hardened alloys and targeted surface treatments like hard chrome plating and ceramic coatings add robust abrasion resistance. Careful selection extends service life, cuts downtime, and reduces maintenance expense.

Optimizing Screw Press Design for Specific Sludge Characteristics and Operational Demands

No single layout fits every application. Effective design comes from aligning the press with sludge characteristics and site requirements. We tailor configurations to address those specifics.

1. Tailoring Screw Design for Municipal Wastewater vs. Industrial Sludge Dewatering

Municipal wastewater sludge blends organic and inorganic solids with varying fiber content. Industrial sludges span a wide range, from oily and greasy to granular or chemically aggressive. Municipal duties often benefit from rugged builds and easy cleaning. For industrial feeds, resistance to targeted chemicals or extreme temperatures takes priority. Our Organic Waste Treatment System and Intelligent Waste Food Treatment System solutions reflect these distinctions.

Achieving Peak Performance: Advanced Screw Design Features and Their Contribution to Dewatering Results

Modern presses use refined geometries and details to push efficiency and reliability. These advances lift cake dryness while simplifying day-to-day operation.

1. The Benefits of Variable Pitch and Shaft Designs for Enhanced Dewatering Efficiency

Variable pitch and shaft profiles raise dewatering efficiency by creating a progressive compression gradient. As pitch tightens and shaft diameter grows toward discharge, pressure builds in a controlled way. That progression maximizes water removal while avoiding premature clogging or excessive pressure spikes. The outcome is a drier cake and steadier operation. We also provide comprehensive Sewage Water Elevating System for integrated waste management.

Frequently Asked Questions

1. What are the primary indicators of poor screw press dewatering performance?

Warning signs include high moisture in the cake, low throughput, excessive solids in the filtrate, frequent clogging, elevated energy draw, and fast screw wear. These issues often trace back to a screw design that does not match the sludge characteristics.

2. How does screw pitch specifically influence the dewatering process?

Screw pitch, the distance between successive flights, sets the compression ratio inside the press. A pitch that decreases through the dewatering zone steadily reduces available volume, raising pressure and expelling more water. An optimized variable pitch helps achieve high cake dryness and effective liquid removal without unnecessary energy use or clogging.

3. Can the material of the screw significantly impact operational costs?

Yes. Screw material determines wear resistance when handling abrasive sludges. Poor material choices accelerate wear, forcing frequent replacements, more downtime, and higher costs. High-grade, wear-resistant options, including selected stainless steel alloys or hardened surfaces, extend service life, reduce lifetime expense, and improve reliability.

4. What is the difference between a constant pitch and a variable pitch screw design?

A constant pitch screw maintains the same spacing between flights from feed to discharge. A variable pitch screw brings flights closer together toward the discharge end. Variable pitch generally improves dewatering by creating progressive compression that increases pressure on the sludge and removes more water, raising cake dryness and efficiency compared to constant pitch designs.

Optimize Your Dewatering Operations

Discover how Shanghai Yimai Industrial Co., Ltd. can optimize your dewatering process with our advanced Double Helix Continuous Presser Machines. Contact us for a consultation tailored to your needs and achieve superior dewatering results.

Email: overseas1@yimaipump.com

Phone/WhatsApp: +86 13482295009