Electric Motors for Sale: A Buyer’s Guide to Industrial Performance

Shopping for electric motors for sale? You’ve probably noticed there’s no shortage of options out there. The real challenge isn’t finding a motor—it’s picking the one that’ll actually work for your operation without breaking the bank or breaking down every few months. Your motor powers everything from pumps to shredders to presses. Get it wrong, and you’re looking at sky-high energy bills, constant maintenance headaches, and equipment that just won’t quit when it should.

This guide cuts through the noise and shows you what actually matters when you’re investing in a motor that needs to perform.

At Shanghai Yimai, we’ve been doing this long enough to know that selling electric motors isn’t the point. The point is solving problems. As a national-level enterprise, we build motors for the tough stuff—municipal water systems, industrial wastewater treatment, and environmental protection equipment. We match the technology to what you’re actually trying to accomplish.

Start with What You’re Actually Running

Before you dive into spec sheets, stop and think about what this motor needs to do. Are you running a centrifugal pump in a booster system? A submersible sewage pump? A double-shaft shredder? The equipment you’re driving matters more than anything else.

Load Type: Is your load steady—like a circulation pump running at one speed all day—or does it change with demand, like a pressure-boosting system?

Operating Hours: Running 24/7 or just a few hours here and there? If it’s continuous, energy efficiency just became your best friend.

Torque Requirements: Do you need serious starting torque? Think fully loaded conveyors or positive displacement pumps like single screw types.

Getting clear on these questions saves you from buying too much motor or not enough.

Understanding High-Efficiency Motor Standards IEC: IE3 vs. IE4

The International Electrotechnical Commission (IEC) sets the standards for motor efficiency. Understanding these ratings is key, whether you’re looking to buy highly efficient three-phase asynchronous motor equipment for a single installation or planning to wholesale high-efficiency three-phase asynchronous motor units for multiple facilities.

IE3 Efficiency (Premium): This is where most industrial motors land today. Our IE3 three-phase asynchronous motor hits this mark—solid performance, reliable operation. It makes sense when upfront cost matters and the motor isn’t running around the clock.

IE4 Efficiency (Super Premium): This is where things get interesting. Our IE4 three-phase asynchronous motors meet this standard and use noticeably less electricity to do the same work. That gap in energy consumption? It turns into real money saved every month. If your motor runs more than a couple thousand hours per year, an IE4 pays for itself fast. For large-scale projects, standardizing on IE4 across the board can cut energy costs significantly.

Three-Phase Asynchronous Motor Applications: The Industry Workhorse

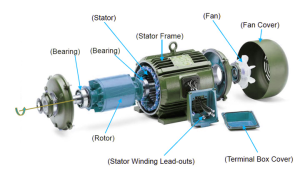

Three-phase asynchronous motors—also called induction motors—are everywhere in industry for good reason. Simple design, tough construction, easy to maintain. They just work.

Our IE3 three-phase asynchronous motor and IE4 series motors are TEFC (Totally Enclosed Fan Cooled) squirrel-cage designs, built for typical industrial conditions. As a high efficient three-phase asynchronous motor factory, we run strict quality checks on every unit. These motors handle:

- Centrifugal pumps (single-stage, multistage, split-case)

- Fans and blowers

- Conveyors

- Compressors

Their straightforward design works with standard power grids, making them versatile for most three-phase asynchronous motor applications. Need something specific for your OEM requirements? We offer customized high-efficiency three-phase asynchronous motor solutions—special voltages, specific paint colors (RAL codes), different mounting setups—whatever your specs call for.

Consider the Motor’s Protection Grade and Operating Environment

Your motor’s enclosure needs to keep the working parts safe from whatever environment you’re throwing it into. That’s where the IP (Ingress Protection) rating comes in. Two digits: the first one covers protection from solids like dust, the second one covers liquids like water.

All our IE3 and IE4 three-phase asynchronous motors carry an IP55 protection grade.

First Digit ‘5’: Dust-protected. Dust can’t get in enough to cause problems with the operation.

Second Digit ‘5’: Protected against water jets. You can spray water at it from any angle without causing damage.

This works for most industrial settings. But if you’re dealing with hazardous locations—explosive gases or combustible dust—you need an explosive protection electric motor. That means working with experienced explosive protection electric motor manufacturers who understand what’s required for safety. Our YBX3 and YBX4 series motors are purpose-built and certified for these conditions. When safety is non-negotiable, you can’t compromise.

Permanent Magnet Synchronous Motor vs Asynchronous: When to Upgrade

Asynchronous motors are the standard, but permanent magnet synchronous motors (PMSMs) take efficiency and control to another level. If you’re considering energy-saving permanent magnetic electric motor suppliers for your next project, look past the spec sheet and understand what you’re actually getting.

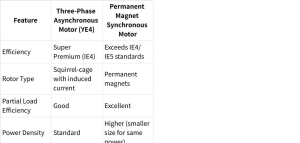

Here’s how they compare, from our perspective as an energy-saving permanent magnetic electric motor factory:

If you’re thinking about whether to buy energy-saving permanent magnetic electric motor technology, here’s what matters: PMSMs eliminate rotor slip losses. That makes them incredibly efficient, especially when they’re not running at full load—which is common in systems where demand varies. For operations needing large quantities, we can wholesale energy-saving permanent magnetic electric motor units for complete facility upgrades. Need something tailored to your specific machinery? We provide customized energy-saving permanent magnetic electric motor solutions matched to your control systems and operational requirements. As leading energy-saving permanent magnetic electric motor manufacturers, we integrate these motors into complete, high-performance pumping solutions.

How to Choose an Industrial Electric Motor for Pumps

Pumps are probably the most common application for electric motors for sale. Getting the motor matched correctly to your pump’s hydraulic requirements means the system actually lasts and runs efficiently.

Determine Power Requirements: Check the pump’s performance curve for the brake horsepower (BHP) needed at your target flow rate and head. Always pick a motor rated higher than the pump’s maximum BHP—typically with a service factor of 1.15.

Match Speed: Most centrifugal pumps in our field run at speeds matching 2-pole (3000/3600 RPM) or 4-pole (1500/1800 RPM) motors. Make sure the motor’s rated speed lines up with what the pump was designed for.

Consider Mounting: Our motors come in standard mounting configurations like IMB3 (foot-mounted), IMB5 (flange-mounted), and IMB35 (foot and flange). This keeps things compatible whether you’re running a single-stage end suction pump or a vertical multistage unit.

Beyond the Motor: The Role of Variable Frequency Drives (VFDs)

If your application sees variable demand, a variable frequency drive (VFD) isn’t optional—it’s essential. A VFD controls motor speed by adjusting the frequency of the power going to it. Instead of running your pump full-blast and choking down the output with a valve, the VFD lets the motor slow down. The energy savings are substantial.

Our variable-frequency motors are built specifically for VFD operation. They have enhanced insulation and cooling to handle the stresses of variable speed work. Pair a IE4 or a Permanent Magnet Synchronous Motor with a VFD, and you’ve got a highly efficient system that delivers exactly what’s needed, when it’s needed. That’s the backbone of our intelligent water supply solutions.

Why Total Cost of Ownership Matters More Than Price

When you’re looking at electric motors for sale, focusing only on the purchase price is shortsighted. Total cost of ownership (TCO) tells the real story.

TCO = Initial Purchase Price + Lifetime Energy Costs + Maintenance Costs

Energy consumption typically runs over 90% of a motor’s lifetime cost. Pay a bit more upfront for a higher-efficiency motor like a IE4 or a PMSM, and you can save thousands in energy costs over its life. Return on investment? Often one to two years. At Shanghai Yimai, we engineer our motors for efficiency and durability because that’s what keeps TCO low for our customers.

Insight: The Future is System-Level Efficiency

The industry’s moving past just specifying a high-efficiency motor. Real performance and energy savings come from optimizing the whole system—motor, drive, and pump working together. IE4 three-phase asynchronous motors delivers excellent efficiency at rated load, but performance can drop at the lower speeds common in variable-demand applications.

This is where our Permanent Magnet Synchronous Motors really shine. Their design maintains superior efficiency across a much wider speed range than even the best asynchronous motors. Integrated into an intelligent pumping house or a frequency-controlled constant pressure water supply system, a PMSM can cut energy consumption by an additional 10-15% compared to an equivalent IE4-powered system. This system-level approach—combining advanced motor technology with smart controls—is where responsible, cost-effective fluid management is headed.

As a leading electric motor manufacturer in China, Shanghai Yimai Industrial Co., Ltd. specializes in providing highly customized motor solutions. We understand the unique demands of global markets and empower your applications with motors that are precisely tailored to your specifications for voltage, power, and mounting configurations. Partner with us to leverage engineering excellence that drives efficiency and reliability.

FAQs

What’s the main difference between the IE3 and IE4 electric motors for sale?

The primary difference is energy efficiency. An IE4 three-phase asynchronous motors (Super Premium Efficiency) wastes less energy as heat and converts more electricity into mechanical work compared to an IE3 three-phase asynchronous motor (Premium Efficiency). This means lower electricity bills, especially if the motor runs long hours.

How do I determine the right motor size for my pump application?

Check the pump’s performance curve to find the brake horsepower (BHP) required at your desired operating point (flow and pressure). Select a motor with a power rating that exceeds this BHP, typically by 10-15%, so it doesn’t run overloaded.

When should I choose a permanent magnet synchronous motor vs an asynchronous one?

Choose a permanent magnet synchronous motor for applications running long hours at variable speeds and loads, like modern booster water systems. While a high-efficiency asynchronous motor (like IE4) works great for constant-load tasks, the PMSM’s superior partial-load efficiency delivers significant additional energy savings in variable-demand scenarios.

What does the IP55 rating mean for an industrial electric motor?

An IP55 rating means the motor is protected against dust ingress and low-pressure water jets from any direction. This makes it durable enough for typical industrial environments like water treatment plants or manufacturing facilities where dust and moisture are present.

Keywords

Primary Keyword: electric motors for sale

Long-Tail Keywords: how to choose an industrial electric motor, high-efficiency motor standards IEC, three-phase asynchronous motor applications, permanent magnet synchronous motor vs asynchronous