High Efficient Three-phase Asynchronous Motor: The Engineering Behind Industrial Energy Savings

The high efficient three-phase asynchronous motor isn’t simply a component—it’s the core of energy management in municipal water supply, wastewater treatment, and industrial fluid transfer. For systems relying on pumps and heavy machinery, motor power consumption often represents 90% or more of lifetime operational costs. As a leading high efficient three-phase asynchronous motor factory, our focus is on engineering solutions that drive down these costs while ensuring continuous, reliable operation.

The Critical Role of the High Efficient Three-phase Asynchronous Motor in Modern Industry

In applications like boosting water systems and operating submersible sewage pumps, motor efficiency directly translates into kilowatts saved per hour. Standard motors—older designs—waste significant energy as heat due to internal resistance in the winding and rotor. The high efficient three-phase asynchronous motor, specifically those meeting IE3 (Premium Efficiency) or IE4 (Super Premium Efficiency) standards, minimize these losses through superior materials and design.

Industrial motors must survive harsh operating environments. Our motors, adhering to standards like IP55 protection, ensure internal components are sealed against dust and water jets. This is crucial for environments common in integrated room pump stations and water treatment facilities, where ingress protection directly relates to operational lifespan and avoiding unplanned downtime.

Core Engineering: What Makes an IE3/IE4 Motor High-Efficient?

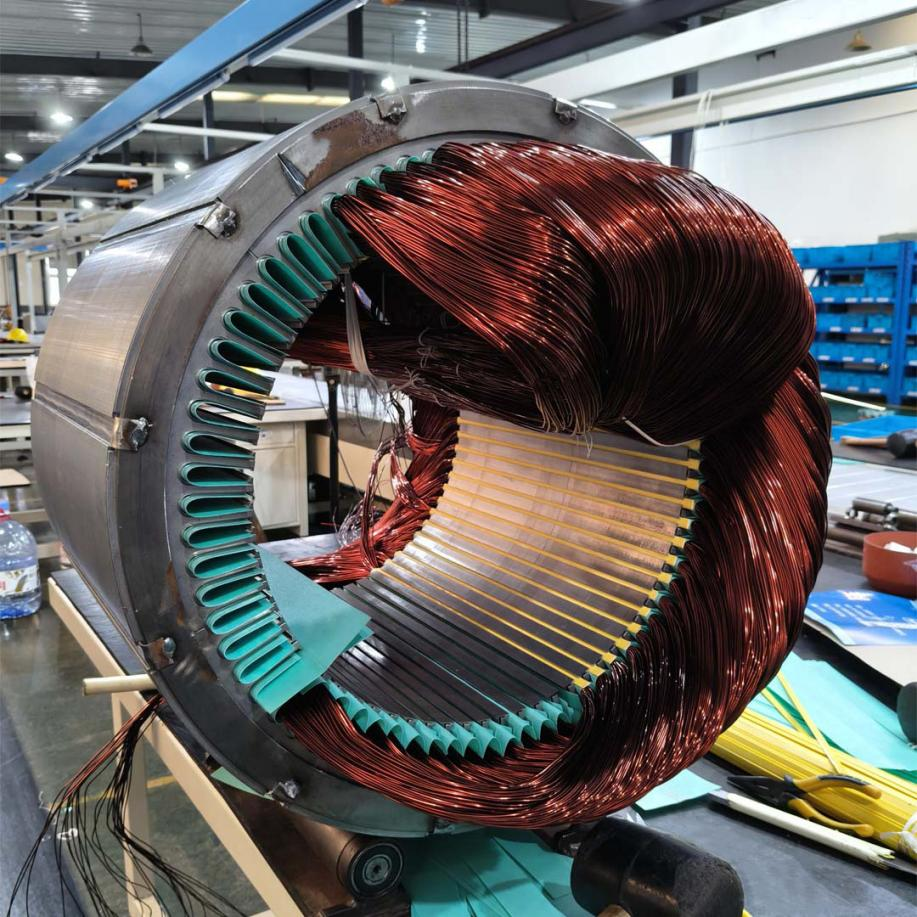

Achieving higher efficiency requires precise engineering changes compared to standard three-phase asynchronous motor designs. These changes target the primary sources of energy loss: copper losses, iron losses, friction, and windage.

Key design elements include:

Higher Quality Copper and Increased Winding Mass: Using larger conductors reduces resistance in the stator winding, directly minimizing heat generation (copper losses).

Improved Core Steel (Iron): Employing thinner, high-grade silicon steel laminations in the rotor and stator reduces magnetic losses (iron losses).

Optimized Air Gap and Rotor Design: Minimizing the air gap and improving the rotor bar shape reduces stray load losses and increases power factor.

Our IE3/IE4 three-phase electric motors embody these principles. Both series feature an IC411 cooling method and F insulation class, standardizing thermal management for longevity. The difference lies in material execution and design refinement: the IE4 series three-phase asynchronous motor targets even smaller loss margins, pushing the efficiency curve higher and delivering maximum energy savings over the motor’s lifespan.

Enhancing Performance with a Variable-Frequency Drive (VFD)

Pairing a high efficient three-phase asynchronous motor with an electric motor controller (Variable-Frequency Drive or VFD) is standard practice for flow-variable applications. In systems like frequency-controlled constant pressure water supply, VFDs adjust motor speed to match real-time demand, significantly reducing power consumption.

A small 20% reduction in speed leads to nearly 50% energy savings. Our variable frequency speed regulating three-phase electric motor is specifically designed for VFD compatibility, ensuring minimal harmonic distortion and stable operation across a wide speed range. This precise control ensures stable water pressure without wasting energy.

Total Cost of Ownership: Beyond the Initial Price Tag

When evaluating which product to source from electric motor suppliers, the focus must shift from purchase price to Total Cost of Ownership (TCO).

| Factor | Standard Motor

(IE1/IE2) |

High Efficient Motor

(IE3/YE3) |

Impact on TCO |

| Energy Consumption | High | Low (e.g., 2-5% lower than IE2) | Major Reduction |

| Lifespan | Standard | Extended (less heat stress) | Reduced Maintenance |

| Purchase Price | Low | Moderate | Negligible over 5+ years |

| Heat Dissipation | High | Low | Reduced HVAC/Cooling Costs |

Over a typical 10-year lifespan, the energy savings from a high efficient three-phase asynchronous motor far outweigh the slightly higher initial cost. This makes the IE3/IE4 three-phase electric motors the only responsible choice for long-term infrastructure investments, especially in public utilities and heavy industry.

Selecting the Right High Efficient Three-phase Asynchronous Motor Factory Partner

Choosing a partner with deep engineering expertise is critical. We don’t just supply motors—we engineer integrated solutions. Our experience as a “Specialized, Refined, Differential, and Innovative Small Giant Enterprise” means we focus on seamless integration into systems like the Integrated room pump station or the Modular integrated water plant. We offer motors in various types, including 2 Pole, 4 Pole, 6 Pole, 8 Pole, and 10 Pole configurations, with IMB3, IMB5, or IMB35 mounting types to ensure compatibility with any pump design, such as a Split casing double suction pump or a Vertical multistage centrifugal pump. We serve as a dependable source for electric motor suppliers globally, providing customized OEM/ODM services.

Maintenance and Longevity: When to Consider an Electric Motor Rebuild

While modern motors are built for longevity, severe operating conditions sometimes necessitate an electric motor rebuild. This process involves replacing core components: bearings, winding, and sometimes the shaft, restoring the motor to its original, or even improved, specifications.

A rebuild is cost-effective when:

- The motor frame and core are structurally sound.

- The motor is a high-power, specialized, or explosion-proof motor, making replacement costly or time-consuming.

- The rebuild can upgrade the motor’s efficiency (e.g., using higher-grade materials), often surpassing the performance of a new, lower-tier motor.

We recommend regular monitoring of vibration and temperature. Early detection of bearing failure can prevent catastrophic breakdown, turning an easy bearing replacement into an extensive and expensive three-phase asynchronous motor rebuild. Our smart systems often include remote diagnostic features that alert engineers before minor issues escalate.

Summary

The adoption of the high efficient three-phase asynchronous motor is an operational necessity, not a luxury. By focusing on superior materials, optimized design, and integration with intelligent controls like VFDs, facilities can drastically cut energy bills and enhance system reliability. From the robust IP55 enclosure to the highly refined winding process, every engineering detail contributes to a lower Total Cost of Ownership and a more sustainable operation.

Expert Insight: The Shift to Ultra-High Efficiency and Permanent magnetic electric motor

The global drive toward decarbonization and reduced industrial power consumption is moving the market rapidly past the IE3 standard. The IE4 three-phase electric motor represents the current benchmark for general-purpose applications. However, the future lies in Permanent magnetic electric motor.

While our IE4 high efficient three-phase asynchronous motor already provides top-tier performance—meeting international standards like IEC60034—Permanent magnetic electric motor offer another leap in efficiency, especially under partial load conditions common in VFD-controlled systems. Permanent magnetic electric motor utilize permanent magnets in the rotor, eliminating the rotor’s winding resistance (copper losses) that’s still present in asynchronous designs.

For the most critical and continuously running applications, such as large-scale municipal water pumping, the slight premium for a permanent magnetic electric motor delivers unparalleled long-term energy savings. We see electric motor controller technology evolving to favor permanent magnet synchronous motor, which offers precise torque and speed control that’s difficult to match with asynchronous motor technology, even the highly efficient IE4. This technology shift ensures our clients remain ahead of tightening energy regulations while achieving minimum environmental footprint.

Need help choosing the right pump or motor? Contact our experts for a personalized solution.

As one of the leading industrial electric motor suppliers, Shanghai Yimai operates a state-of-the-art electric motor factory dedicated to innovation and quality. We offer a comprehensive range of high-performance motors, ensuring you find the precise power solution for your needs. Partner with us for reliable supply and expert technical support that streamlines your procurement chain.

Dynamic FAQs

Q1: What is the difference between an IE3 and an IE4 high efficient three-phase asynchronous motor?

A: The difference is the efficiency level defined by the IEC standard. IE4 three-phase electric motors have significantly higher minimum efficiency than IE3 three-phase electric motors. This higher efficiency is achieved through superior materials, tighter tolerances, and more refined electromagnetic design, resulting in even lower heat waste and greater energy savings. While both are highly efficient, the IE4 offers the lowest operational power consumption.

Q2: Does a VFD require a special type of electric motor controller?

A: Yes. While a standard three-phase asynchronous motor can technically run on a VFD, to ensure long-term reliability and achieve maximum benefit, you need a variable frequency speed regulating electric motor. These motors have features like improved winding insulation (often able to handle high voltage spikes from the VFD output) and enhanced thermal design for operation at low speeds, preventing premature failure and making the whole system more resilient.

Q3: When is an electric motor rebuild more cost-effective than buying from electric motor suppliers?

A: A professional electric motor rebuild is typically more cost-effective for large, high-voltage, or specialized motors (such as Explosion-Proof Motors) where replacement cost and lead time are substantial. If the motor is still under 50 HP and readily available from electric motor manufacturers, a new IE4 three-phase asynchronous motor may be the best choice to lock in the highest possible energy savings. For any major industrial asset, a TCO analysis should be performed to make the final determination.