How to Find Reliable Electric Motors for Sale?

I’ve been in the motor business for over two decades, and I can tell you that finding reliable electric motors for sale is trickier than most procurement managers realize. It’s not just about checking boxes on a spec sheet or finding the lowest price. After manufacturing thousands of motors and working with clients across six continents, I’ve learned what separates motors that run for decades from those that fail within months.

I want to share the insider knowledge that can save you from costly mistakes. Whether you’re sourcing standard industrial units or need a specialized small electric motor, the fundamentals remain the same: quality starts at the source, not at the point of sale.

Why “Electric Motors Near ” Doesn’t Mean What You Think

Every week, I get calls from buyers searching for “electric motors near” because they think geographic proximity equals faster delivery. After shipping motors worldwide for years, I can tell you this assumption often leads to disappointment.

Here’s what “near me” really should mean in today’s market:

Standardized Production That Actually Works We maintain standardized production lines because consistency matters more than convenience. When a client in Germany needs the same motor we shipped to Texas last month, they get identical quality and performance. This standardization lets us fulfill orders faster than many local distributors who juggle multiple supplier relationships.

Logistics That Make Distance Irrelevant I’ve invested heavily in international shipping partnerships and warehousing solutions. We can get electric motors for sale to most global destinations faster than local suppliers who rely on third-party distributors. When you factor in customs documentation and compliance certifications, our integrated approach often beats “nearby” options.

Support That Follows Your Motors What good is a local supplier if they can’t provide technical support? We work with service partners worldwide who understand our motors inside and out. When you need installation guidance or maintenance support, you get expertise, not guesswork.

The most reliable motor source is one that treats manufacturing consistency and supply chain efficiency as equal priorities. Geography matters less than capability.

What I Actually Look For When Evaluating Electric Motors for Sale?

After years of helping clients avoid costly motor failures, I can tell you that most buyers focus on the wrong specifications. Price and delivery time matter, but they’re meaningless if the motor fails six months after installation.

Here’s what I verify on every motor before it leaves our facility:

Protection Grade – The IP Rating Reality Check Most industrial environments need at least IP55 protection. This isn’t marketing fluff—it’s the difference between a motor that handles dust and moisture versus one that fails the first time conditions get challenging. I’ve seen too many “bargain” motors fail because buyers didn’t understand what IP ratings actually mean.

Insulation Class – Your Insurance Policy We use F class insulation as standard because thermal performance determines motor lifespan. Higher-rated insulation provides a safety margin that prevents premature failure when operating conditions aren’t perfect—which they never are in real-world applications.

Cooling Method – Heat Management Done Right Our IC411 (Totally Enclosed Fan Cooled) design isn’t the cheapest option, but it’s the most reliable for sustained operation. I’ve seen too many electric motors overheat because manufacturers cut corners on cooling systems.

Standards Compliance – Non-Negotiable Foundation Every motor we produce complies with IEC60034/IEC60072 specifications. This ensures performance characteristics are accurately rated and internationally compatible. When you see motors without clear standards compliance, walk away.

These specifications appear on every motor rating plate and in our technical documentation. When suppliers can’t provide this data clearly, they’re telling you something about their quality standards.

The Small Electric Motor Selection Mistakes That Cost You Big

Buyers often treat small electric motor selection (under 15 kW) as a commodity purchase. This mindset leads to expensive mistakes. I’ve helped clients replace “budget” motors multiple times when a quality unit would have run for years without issues.

Here’s what I focus on for every small electric motor we produce:

Duty Cycle – Get This Wrong and You’re Buying Again Soon Most industrial applications require S1 (Continuous Duty) rating. This means the motor runs indefinitely at rated load without overheating. I’ve seen buyers choose cheaper S2-rated motors for continuous applications, then wonder why they’re replacing motors every few months.

Mounting Standards – Compatibility Matters We provide standard mounting options like IMB3 (foot-mounted) and IMB5 (flange-mounted) because replacement motors need to fit existing equipment without modifications. When suppliers offer “custom” mounting that’s actually non-standard, you’re locked into their supply chain forever.

VFD Compatibility – The Hidden Requirement Many small electric motor applications now use Variable Frequency Drives for control and energy savings. The motor insulation must handle harmonic distortion and voltage spikes from VFDs. We design this compatibility into every motor because retrofit failures are expensive and disruptive.

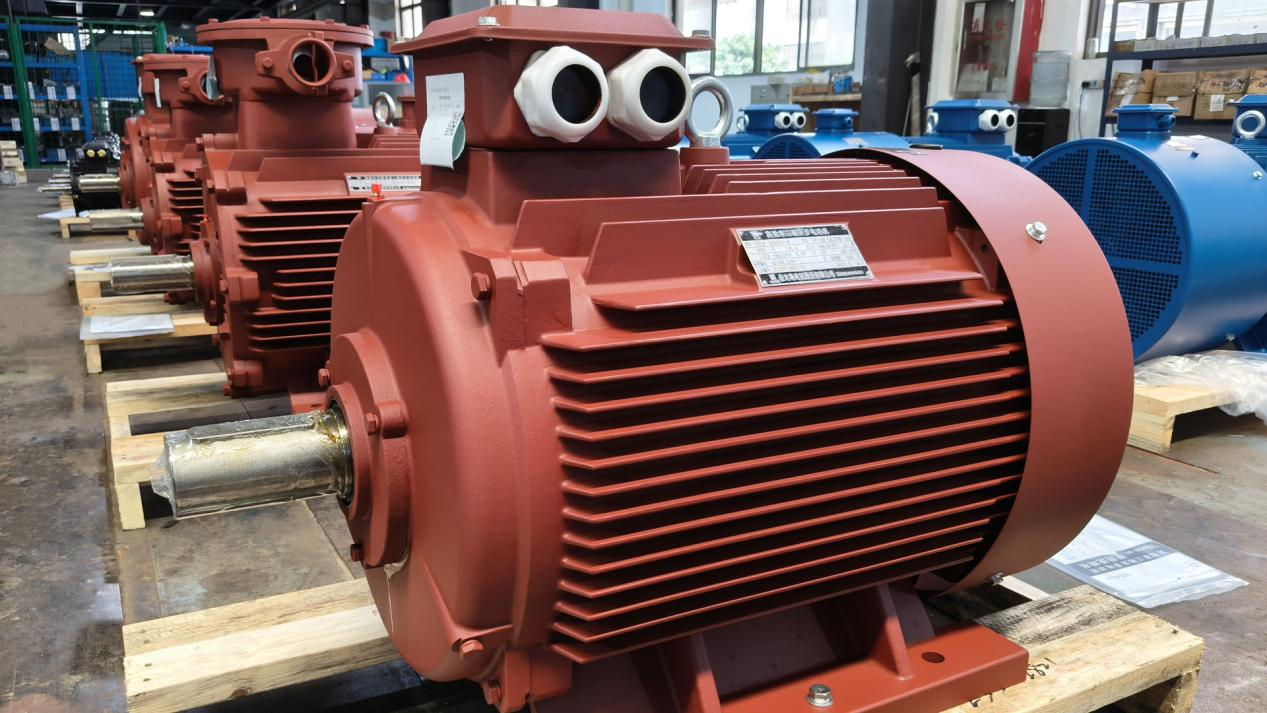

Quality in a small electric motor comes from applying the same material standards and manufacturing rigor we use for larger units. Our Three-Phase Asynchronous Motor components deliver consistent performance because we don’t compromise on fundamentals.

The Strict Quality Control Process of Our Electric Motor

When evaluating electric motors for sale, you’re really evaluating the manufacturer’s quality control. Low prices often hide compromises in materials and testing that will cost you later.

Here’s our quality process that every motor goes through:

Material Inspection – It Starts With the Right Components We verify every component—copper wire, steel laminations, bearings—meets grade requirements for the specified insulation class and expected service life. Cheap materials create expensive failures.

In-Process Quality Control – Catching Problems Early We monitor critical stages, especially winding and impregnation processes. These determine thermal performance and moisture resistance. Problems caught during manufacturing cost pennies to fix; problems caught in the field cost thousands.

Final Factory Testing – Every Motor, Every Time Every unit undergoes mandatory final testing: no-load current checks, insulation resistance tests, and vibration analysis. This confirms mechanical integrity before shipping. We don’t spot-check—we test everything.

Digital Traceability – Accountability That Follows Your Motor Every motor has digital records covering components, production date, and test results. When issues arise—and occasionally they do—we can trace problems to their source quickly. This accountability is what separates professional manufacturing from commodity production.

This factory-based quality control eliminates guesswork. Whether you found us by searching “electric motors near me” or through international channels, you get the same verified quality.

Continuous Improvement–Feedback Loops from the Field

Our quality process doesn’t end at shipping. We collect data from installations worldwide, analyzing performance and failure cases. This real-world feedback gets fed directly into R&D and production improvements, ensuring each generation of motors is more reliable than the last.

Why IE3/IE4 Efficiency Standards Matter Even for Small Electric Motor Applications?

Energy efficiency regulations are tightening globally, and I’m seeing clients who bought cheap, inefficient motors face compliance issues and high operating costs. Even in the small electric motor category, where buyers traditionally focused on upfront cost, efficiency standards are becoming mandatory.

Smart buyers prioritize manufacturers whose entire product line complies with IE3 and IE4 requirements. We’ve built our manufacturing around these standards because retrofitting inefficient motors later is expensive and disruptive.

The trend toward small electric motor integration with Variable Frequency Drives is accelerating this shift. We design VFD compatibility into every unit because the combination delivers both regulatory compliance and significant energy savings.

Investing in compliant, efficient motors now prevents costly retrofits and penalties later. After two decades in this business, I’ve learned that taking shortcuts on efficiency standards always costs more in the long run.

Our Yimai stands as a premier industrial electric motor manufacturer. Yimai motors are engineered for exceptional energy efficiency and high performance in demanding applications. By focusing on precision and durability, we deliver robust motor solutions that directly contribute to lower electricity consumption and reduced downtime, ensuring your operations remain productive and cost-effective.

Common Questions I Get About Electric Motor Sourcing

How can I verify the quality of electric motors for sale from suppliers I haven’t used before?

Demand documentation proving IP protection grade (like IP55), insulation class (such as F), and compliance with IEC60034 standards. Most importantly, ask about their final factory acceptance testing process. If they can’t show you how every unit is individually tested before shipping, find another supplier. Quality manufacturers are proud of their testing protocols.

What specifications matter most when I’m selecting a small electric motor?

Focus on Duty Cycle (S1) for continuous operation capability and control compatibility if you’re using VFDs. The motor insulation must handle voltage stresses from VFDs to prevent premature winding failure. Don’t let suppliers talk you into “adequate” ratings—get what you actually need for reliable operation.

Will searching for “electric motors near me” guarantee faster delivery?

Geographic proximity doesn’t guarantee speed—supply chain efficiency does. Local distributors often depend on multiple suppliers and face inventory limitations. Manufacturers with standardized production and integrated logistics can deliver quality electric motors for sale faster than smaller local vendors. Focus on capability, not location.

Keywords

electric motors for sale,electric motors near me, small electric motor, industrial motor fulfillment