IoT in Water Treatment: Modern Water Plants Need Smart Solutions

The landscape of water treatment is undergoing a significant transformation, driven by the integration of advanced technologies. Modern water plants increasingly require sophisticated systems to ensure efficiency, reliability, and sustainability. The IoT in water treatment represents a pivotal shift, moving from reactive maintenance to proactive management. This evolution demands intelligent infrastructure capable of real-time monitoring, data analysis, and automated control.

For decades, water treatment facilities relied on manual inspections and scheduled maintenance. This approach often led to delayed issue detection, increased operational costs, and potential service disruptions. The advent of the Internet of Things (IoT) provides a powerful solution, enabling comprehensive oversight and optimization of water infrastructure. We understand these challenges and offer solutions that enhance operational intelligence and resource management.

Real-time Monitoring and Data Acquisition in Water Systems

Real-time monitoring forms the cornerstone of effective IoT implementation in water treatment. Sensors deployed throughout the plant collect vast amounts of data on critical parameters such as water quality, flow rates, pressure, and equipment status. This continuous data stream allows operators to gain immediate insights into system performance. For instance, our VFD Controlled Booster System, with its pressure adjustment accuracy of ≤0.01 MPa, integrates seamlessly with IoT platforms to provide precise data on water pressure fluctuations. This precision is crucial for maintaining consistent water supply and preventing system overloads.

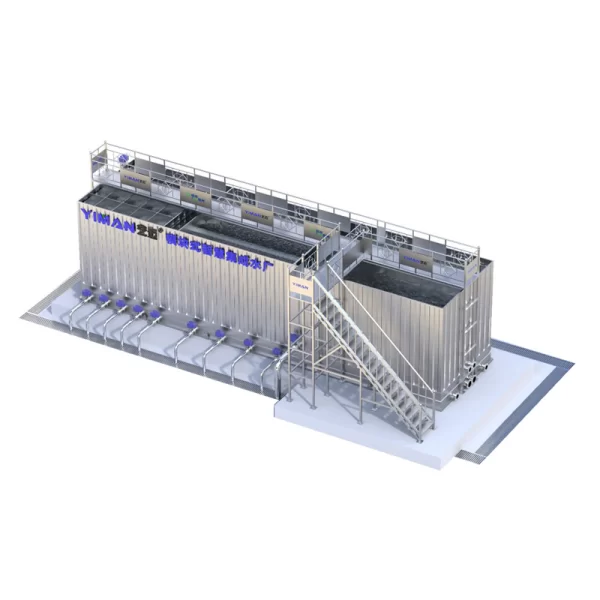

The ability to acquire data instantaneously minimizes response times to anomalies. For example, sudden drops in pressure or unexpected changes in water quality can be detected within seconds, triggering alerts for immediate investigation. This proactive approach significantly reduces the risk of equipment failure and ensures compliance with stringent water quality standards. The integration of IoT sensors with our Modular Integrated Water Plant allows for unattended and intelligent operation and maintenance, providing real-time data on effluent turbidity, which consistently remains ≤0.1 NTU.

Predictive Maintenance with Smart Sensors

Predictive maintenance, enabled by IoT, moves beyond traditional scheduled maintenance. Instead of replacing components based on fixed intervals, smart sensors monitor equipment health and predict potential failures. Vibration sensors on pumps, for example, can detect early signs of wear and tear, allowing for maintenance to be scheduled precisely when needed, rather than too early or too late. This optimizes maintenance costs and extends the lifespan of valuable assets.

Consider a Centrifugal Pump in a water treatment facility. Traditionally, its maintenance schedule might be based on hours of operation. With IoT, embedded sensors track its performance metrics, such as bearing temperature and motor current. If these parameters deviate from established baselines, the system flags a potential issue, allowing technicians to intervene before a catastrophic failure occurs. This approach reduces downtime and avoids costly emergency repairs.

Automated Control Systems for Enhanced Efficiency

Automation is a natural extension of IoT capabilities in water treatment. Smart control systems analyze data from connected sensors and adjust operational parameters automatically. For example, if water demand increases, the system can automatically activate additional pumps or adjust pumping speeds to maintain optimal pressure. This reduces human intervention, minimizes operational errors, and enhances overall system efficiency.

Our Intelligent Digital Driven VFD Booster System exemplifies this automation. It dynamically adjusts pump operation based on real-time demand, ensuring optimal energy consumption. With a flow range of 5 to 900+ m³/h and power options from 0.37 kW to 22 kW, these systems can be precisely scaled to various plant needs. The system’s internal CAN and external RS485 communication methods facilitate seamless integration into broader IoT networks, enabling remote management and data exchange.

Optimizing Water Quality Monitoring and Compliance

Maintaining stringent water quality standards is paramount in water treatment. IoT devices play a critical role in enhancing water quality monitoring. Specialized sensors can continuously measure parameters like pH, chlorine levels, turbidity, and dissolved oxygen. This data is transmitted to a central platform, providing a comprehensive overview of water quality across different stages of treatment and distribution.

The ability to monitor water quality in real-time ensures immediate detection of contaminants or deviations from acceptable levels. Automated alerts can be configured to notify operators if any parameter falls outside the defined range, allowing for swift corrective actions. This not only safeguards public health but also ensures compliance with regulatory requirements, avoiding potential penalties and reputational damage.

Remote Management and Operational Visibility

IoT in water treatment offers unparalleled remote management capabilities. Operators can monitor and control various aspects of the plant from a centralized control room or even via mobile devices. This significantly improves operational flexibility, especially for geographically dispersed facilities or during off-hours. Remote diagnostics also allow experts to troubleshoot issues without needing to be physically present at the site.

For example, a Prefabricated pump station located in a remote area can be fully monitored and controlled from a central hub. Parameters such as pump status, flow rates, and energy consumption are accessible remotely. This reduces the need for frequent site visits, saving time and resources. The integrated compact design and intelligent operation of our prefabricated pump stations are specifically designed to facilitate such remote management, offering processing capacities from 50 to 100,000 m³/day.

Enhancing Energy Efficiency and Sustainability

Energy consumption is a significant operational cost for water treatment plants. IoT solutions contribute substantially to improving energy efficiency. By optimizing pump operations, detecting leaks, and managing chemical dosing more precisely, plants can reduce their energy footprint. For instance, intelligent control of VFD Controlled Booster System can lead to substantial energy savings by matching pump output to actual demand, rather than operating at constant maximum capacity.

Furthermore, IoT helps in identifying areas of energy waste and implementing corrective measures. Data analytics can reveal patterns of inefficient operation, allowing plant managers to fine-tune processes and reduce overall energy consumption. This commitment to sustainability aligns with global efforts to minimize environmental impact and conserve natural resources.

Cybersecurity Considerations in IoT Deployments

While the benefits of IoT in water treatment are substantial, cybersecurity remains a critical concern. Connected systems can be vulnerable to cyberattacks, potentially disrupting operations or compromising sensitive data. Therefore, robust cybersecurity measures are essential for any IoT implementation. This includes secure network architectures, encryption protocols, access controls, and regular security audits.

We prioritize the security of our IoT-enabled solutions. Our systems are designed with multiple layers of protection to safeguard against unauthorized access and cyber threats. Continuous monitoring and updates ensure that our infrastructure remains resilient against evolving security challenges. Protecting these critical systems is not just about data; it’s about safeguarding public health and essential services.

From Our Field Engineers: Practical IoT Implementation Tips

“From our experience deploying IoT solutions in diverse water treatment environments, a phased approach yields the best results. Start with critical areas like pumping stations or filtration units. Implement smart sensors for real-time data collection and then gradually integrate automated controls. For instance, we recently helped a municipal water plant integrate Vertical Multi-Stage Centrifugal Pump with an IoT platform. By monitoring vibration and temperature, they reduced unscheduled downtime by 20% within the first year. The key is to leverage actionable insights from the data, not just collect it.”

This practical advice underscores the importance of strategic implementation and continuous optimization. The initial investment in IoT infrastructure pays dividends through improved operational performance and reduced long-term costs.

The Future of Smart Water Infrastructure

The future of water treatment is undeniably linked to the continued advancement and adoption of IoT technologies. As sensors become more sophisticated, data analytics more powerful, and AI integration more seamless, water plants will evolve into highly autonomous and resilient systems. This will enable them to better address challenges such as water scarcity, aging infrastructure, and increasing regulatory demands.

The convergence of IoT with other technologies like artificial intelligence and machine learning will unlock even greater potential. Predictive models will become more accurate, allowing for even more precise control and optimization. This evolution will lead to more sustainable water management practices globally.

Expert Insight: The Value of Integrated Solutions

The true value of IoT in water treatment lies not just in individual smart devices, but in the integration of these devices into a cohesive, intelligent system. A fragmented approach, where various components operate in silos, diminishes the overall benefit. For example, a stand-alone sensor might provide data, but without integration into a broader control system, its impact is limited. Our approach focuses on providing comprehensive, integrated solutions, from advanced pumps like the Split casing double suction pump (with max flow rates up to 3975 m³/h) to intelligent control systems. This ensures that every component works in harmony, maximizing efficiency and reliability. The synergy between hardware and software is critical for realizing the full potential of a smart water plant.

Why Modern Water Plants Need Intelligent Solutions

Modern water plants operate under increasing pressure to deliver safe, clean water efficiently and sustainably. The challenges range from aging infrastructure and rising operational costs to stricter environmental regulations and growing water demand. Traditional operational models are often insufficient to meet these complex requirements. This is where IoT in water treatment becomes indispensable.

IoT solutions provide the tools necessary to overcome these hurdles. They enable precise control, predictive maintenance, and real-time insights, transforming water treatment from a resource-intensive process into a data-driven, optimized operation. This leads to significant cost savings, improved service reliability, and enhanced environmental stewardship.

Contact Our Experts for Smart Water Solutions

We specialize in providing integrated solutions for modern water treatment facilities. Our expertise spans from high-efficiency pumps and motors to advanced IoT-enabled control systems. We are committed to helping you implement smart solutions that enhance your plant’s performance and sustainability. Contact our specialists to explore tailored solutions.

FAQs

Q1: What is the primary benefit of IoT in water treatment?

A1: The primary benefit is enhanced operational efficiency and reliability through real-time monitoring, data-driven insights, and automated control, leading to reduced costs and improved water quality.

Q2: How does IoT improve water quality monitoring?

A2: IoT integrates various sensors to continuously measure parameters like pH, chlorine, and turbidity, providing immediate alerts for deviations and ensuring compliance with quality standards.

Q3: What role does predictive maintenance play in smart water plants?

A3: Predictive maintenance uses IoT sensors to monitor equipment health and forecast potential failures, allowing for proactive maintenance scheduling, reduced downtime, and extended equipment lifespan.

Q4: What kind of equipment can be integrated with IoT in a water plant?

A4: Almost all critical equipment, including pumps (like Vertical Multi-Stage Centrifugal Pump), motors, filtration units, and chemical dosing systems, can be integrated with IoT sensors and control modules.

Q5: How does IoT contribute to energy savings in water treatment?

A5: IoT optimizes pump operations, detects leaks, and precisely manages processes like chemical dosing, thereby reducing overall energy consumption and operational costs.

Keywords

Keyword: IoT in water treatment, modern water plants, smart water infrastructure, water quality monitoring, predictive maintenance