Selecting Municipal Wastewater Treatment Pumps

Choosing the right pump for a municipal wastewater treatment plant is one of the most important decisions you will make. An incorrect choice leads to frequent clogs, high maintenance costs, system downtime, and excessive energy consumption. The goal is to select a pump that handles the specific fluid conditions with maximum reliability and efficiency. This guide will walk you through the essential factors we consider in our work, based on our decades of experience.

The process is not as simple as matching a pump to a pipe diameter. It requires a deep understanding of the fluid itself—what we call the “pumped medium”—and the specific function of the pump within the system.

Understanding Your Fluid and Application

Before we look at a single pump, we first analyze the fluid being handled. Wastewater is a complex mixture of water, solids, rags, and chemicals. The characteristics of this fluid directly dictate the type of pump you need.

Solids Content: This is the most critical factor. Is the wastewater raw sewage with high solid concentrations, or is it treated effluent with minimal solids? The size and type of solids (fibrous materials, grit, large objects) will determine the necessary pump and impeller design. For example, a pump handling only pre-screened effluent can use a different impeller than a pump in a raw sewage lift station.

Corrosiveness and pH: Municipal sewage can be corrosive due to the presence of chemicals and hydrogen sulfide gas. The pump materials must be resistant to this environment to prevent premature failure.

Abrasiveness: Grit and sand can cause significant wear on impellers and casings, leading to a loss of efficiency and a shorter pump life. We must choose materials that can withstand this abrasion.

Temperature and Viscosity: While less common in municipal wastewater, extreme temperatures or high viscosity fluids (like sludge) require special pump types and material considerations.

Once we understand the fluid, we pinpoint the pump’s role. Is it a main lift station pump, a recirculation pump for aeration basins, or a transfer pump for thickened sludge? Each application has different requirements for flow, head, and operational cycles.

Matching the Right Pump Type to the Job

The diverse applications within a wastewater plant demand different pump technologies. The most common pump type for moving raw sewage is the submersible sewage pump. Designed to operate completely submerged, these pumps are installed directly in the wet well, eliminating the need for a separate pump house and complex suction piping.

For systems with a high content of rags and fibrous materials, a standard non-clogging pump may not be enough. In these cases, we often recommend a heavy-duty cutting submersible sewage pump. These pumps are equipped with a cutter mechanism at the suction inlet that shreds solids and rags, preventing them from clogging the impeller and discharge pipe.

For high-viscosity media like dewatered sludge, a centrifugal pump is often unsuitable. Instead, we use a positive displacement pump such as a stainless steel single screw pump. This technology provides a constant, pulsation-free flow, regardless of the fluid’s viscosity, which is essential for dosing and transfer applications.

The Role of Impeller Design for Solids Handling

A pump is only as good as its impeller. The impeller design is a critical component in the ability of a municipal wastewater treatment pumps to handle solids.

Vortex Impeller: This design creates a whirlpool effect that pulls solids into the volute and through the pump with minimal contact with the impeller vanes. It’s excellent for preventing clogs, especially with long, stringy solids, though it is less efficient than a channel impeller.

Channel Impeller: A channel or open impeller design has large, open passages that allow solids to pass through easily. These are more efficient than vortex impellers and are a common choice for wastewater applications with large but manageable solids.

Recessed or Cutter Impeller: For the toughest applications, a recessed or cutter impeller is used. The recessed impeller creates a vortex to keep solids away, while the cutter impeller physically breaks down solids before they enter the pump. This is the ultimate solution for ragging issues.

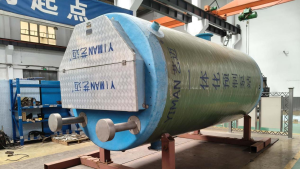

Cast Iron Submersible Sewage Pump

integrated prefabricated pumping station

Choosing Materials for Ultimate Corrosion and Wear Resistance

The materials of construction determine a pump’s durability and lifespan in a corrosive or abrasive environment. A standard cast iron pump may suffice for some general applications, but it is often not enough for long-term reliability in municipal wastewater.

We offer a range of materials based on the application’s demands:

Cast Iron Submersible Sewage Pump:

This is a robust and cost-effective option for general municipal wastewater. It provides good resistance to abrasion and is suitable for most raw sewage applications.

304 Stainless Steel Submersible Sewage Pump:

For moderately corrosive wastewater, such as from certain industrial discharges or environments with high chloride content, 304 stainless steel offers better corrosion resistance than cast iron.

316L Stainless Steel Submersible Sewage Pump:

This is our go-to material for highly corrosive or aggressive media. The molybdenum content in 316L provides superior resistance to pitting and crevice corrosion, making it suitable for chemical transfer, industrial wastewater, and applications with low pH levels.

Motor Selection and Its Impact on Safety and Performance

The pump motor must be correctly specified for the operating environment. In some wastewater treatment facilities, especially those dealing with raw sewage, methane gas can be present, creating a hazardous environment. In these cases, an explosion-proof asynchronous motor is not just a recommendation; it is a necessity.

Our three-phase explosion-proof asynchronous motors are designed and certified for such hazardous locations. They prevent internal explosions from igniting the external atmosphere, ensuring the safety of your facility and personnel.

Furthermore, we consider motor efficiency. Using an ultra-high efficiency motor, such as our IE4 three-phase asynchronous motor, significantly reduces the energy consumption of a pumping station over its lifetime. When paired with a variable frequency drive (VFD), these motors can be precisely controlled to match the flow demand, maintaining a stable water level and preventing the pump from running at full speed unnecessarily.

Prioritizing Reliability and Ease of Maintenance

A pump’s value isn’t just its initial cost; it’s its total cost of ownership (TCO). A pump that requires constant maintenance or is difficult to service will cost you far more in the long run due to downtime and labor.

When selecting a submersible sewage pump, we look for designs that offer:

Ease of Access: Components like impellers and mechanical seals should be easy to inspect and replace without needing to completely dismantle the pump or remove it from the wet well.

Robust Seals and Bearings: High-quality mechanical seals and bearings are essential to prevent leaks and ensure the motor’s longevity. Our pumps often feature double mechanical seals in an oil chamber for enhanced protection.

Self-Cleaning Features: Some pump systems and wet well designs incorporate features that prevent solids from settling, minimizing the need for manual cleaning.

Selecting a pump for municipal wastewater treatment is a methodical process. It starts with a detailed analysis of the fluid and application, leads to the careful selection of pump and impeller types, and culminates in a focus on long-term reliability and efficiency. By following these steps and working with a knowledgeable partner, you can ensure your system is robust, safe, and cost-effective for years to come.

Yimai Expert Insight: The Future of Wastewater Pumping: From Pumps to Integrated Stations

The traditional approach of selecting a standalone pump and motor is giving way to a more holistic, integrated system design. The future of municipal wastewater pumping is not in individual components, but in complete, intelligent, pre-engineered solutions. We are seeing a major shift towards integrated prefabricated pumping station solutions.

These systems are manufactured off-site and delivered as a single, drop-in unit. They include the pumps, internal piping, valves, and a sophisticated control panel all housed within a sealed, corrosion-resistant fiberglass or polyethylene tank. This approach drastically reduces on-site construction time and complexity, lowers overall project costs, and improves system reliability.

Furthermore, these integrated stations incorporate smart technology from the ground up. They are often equipped with intelligent controls that can communicate remotely with a central monitoring system. This allows for real-time performance monitoring, predictive maintenance alerts, and automatic adjustments to optimize energy consumption. For example, a system can be programmed to use our IE4 series three-phase asynchronous motor and a VFD to precisely match the pump speed to the incoming flow, reducing energy consumption during low-flow periods. According to our internal testing, a system using a IE4 three-phase asynchronous motor motor with intelligent control can reduce energy consumption by up to 30% compared to a conventional IE3 series three-phase asynchronous motor system operating without frequency control. This not only lowers operational costs but also provides a sustainable solution for a city’s critical infrastructure.

Pioneering the Future of Water Systems for 20 Years. As the submersible sewage pump supplier China, we combine cutting-edge technology with robust engineering to create high quality sewage pump solutions that set new standards in efficiency and sustainability for your projects!

FAQs

- What is the difference between a standard and a heavy-duty cutting submersible sewage pump?

A standard submersible sewage pump is designed to handle wastewater with solids but may struggle with high concentrations of fibrous materials like rags and wipes. A heavy-duty cutting submersible sewage pump has a built-in cutter mechanism that shreds these tough solids before they reach the impeller, preventing clogs and ensuring uninterrupted operation.

- Is an explosion-proof motor always necessary for a sewage lifting system?

Yes, in most cases, an explosion-proof motor is required. A sewage water elevating system often operates in a confined space (the wet well) where flammable gases like methane can accumulate from the breakdown of organic waste. To prevent sparks from the motor from igniting these gases, a certified explosion-proof motor is essential for safety.

- How does pump material affect long-term maintenance costs?

The pump material directly impacts its resistance to corrosion and abrasion. Choosing a material like 316L stainless steel submersible sewage pump for a corrosive application, even though it has a higher initial cost, will lead to significantly lower maintenance and replacement costs over the pump’s lifetime. A pump with inadequate material will wear out quickly, requiring frequent repairs or early replacement.

Keywords: Primary: municipal wastewater treatment pumps

Long-Tail: wastewater pump selection, submersible sewage pump, pump material for sewage, explosion-proof motor for wastewater