Top 15 Questions Industrial Buyers Ask Before Purchasing a Horizontal Split Casing Double Suction Pump

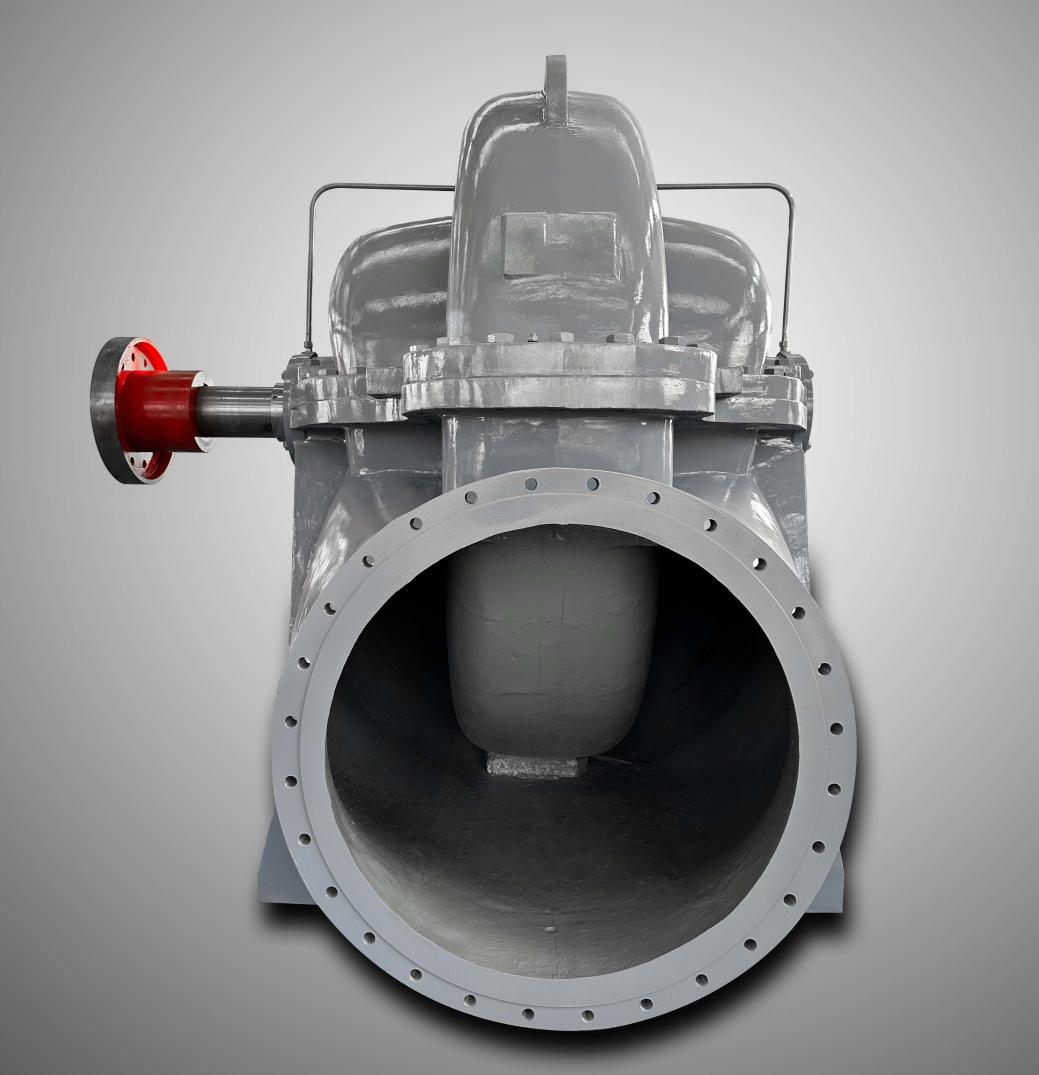

When it comes to selecting the right Horizontal Split Casing Double Suction Pump, industrial buyers and engineers know that performance, reliability, and efficiency make all the difference. Whether used for municipal water supply, HVAC systems, industrial circulation, or firefighting applications, a properly selected Double Suction Centrifugal Pump ensures stable flow and long-term performance.

Here are the top 10 questions B2B customers commonly ask before making their investment in a Horizontal Split Casing Pump or Split Casing Double Suction Pump.

What Flow Rate and Head Can the Horizontal Split Case Double Suction Pump Provide?

Flow and head are the foundation of every pump selection. Buyers need to know the capacity range, head pressure, and efficiency curve of the Double Suction Centrifugal Pump to ensure it matches their system requirements. A properly sized Split Casing Double Suction Pump minimizes energy waste and delivers consistent performance.

What Is the Efficiency and Energy Consumption?

For large-scale water supply systems or industrial circulation, energy efficiency is critical. A well-designed Double Suction Pump System reduces power costs and enhances overall operational stability. Buyers need to compare the hydraulic efficiency and motor power requirements of different Horizontal Split Casing Pumps before deciding.

What Is the Material Configuration of the Pump?

Industrial users need care about material selection—for example, cast iron, ductile iron, or stainless steel casings, and bronze or stainless-steel impellers.

The Horizontal Split Casing Centrifugal Pump must resist corrosion, especially for sea water, industrial cooling, or slightly contaminated liquids. The right material ensures durability and low maintenance costs.

What Are the Pressure and Temperature Limits?

Depending on the application, buyers will ask about the maximum operating pressure, temperature range, and shaft sealing options. The Double Suction Split Casing Pump must handle the required duty without cavitation or leakage—especially in high-pressure HVAC or firefighting systems.

Can the Pump Be Driven by an Electric Motor or Diesel Engine?

Many B2B clients need flexibility. They often ask if the Horizontal Split Casing Double Suction Pump can be coupled with diesel engines, variable frequency drives (VFDs), or direct electric motors.

A modular Double Suction Centrifugal Pump setup allows easy integration into existing systems.

Is the Horizontal Split Casing Pump Easy to Maintain?

Because these pumps are used in continuous operation, maintenance efficiency is essential.

The split casing design allows engineers to open the pump horizontally for quick inspection of the impeller, shaft, and bearings—without disturbing the pipe alignment.

That’s why the Horizontal Split Casing Pump is preferred for municipal and industrial applications.

What Certifications and Quality Standards Does It Meet?

Serious buyers look for pumps that meet ISO, CE, UL, or API standards.

Certified Double Suction Split Casing Pumps indicate reliable performance and quality assurance. Many customers also ask for test reports, factory inspection certificates, and performance curves before approval.

What’s the Delivery Time and OEM/ODM Capability?

Wholesalers and project contractors care about lead time, MOQ, and customization.

Manufacturers of Horizontal Split Casing Double Suction Pumps that offer OEM branding, custom flange sizes, or specific voltage configurations gain a competitive edge in the global market.

Can You Provide Technical Support and After-Sales Service?

A reliable Double Suction Centrifugal Pump Manufacturer should provide full technical support—from installation guidance to commissioning assistance and spare parts supply.

For overseas clients, long-term after-sales service and remote support build trust and ensure smooth system operation.

What Are the Typical Applications and Reference Projects?

Buyers often ask where the Horizontal Split Casing Pump has been successfully applied.

Common industries include municipal water treatment, power plants, HVAC, irrigation, fire protection, and industrial cooling systems.

Case studies and reference projects help confirm the reliability of the Large Flow Double Suction Pump in real-world operations.

What are the bearing life, seal type, and lubrication method?

Industrial users know that bearings and seals are critical components for ensuring continuous pump operation and minimizing maintenance frequency.

They will ask about the designed L10 bearing life, the type of sealing employed (e.g., packing, single mechanical seal, or double mechanical seal). Furthermore, the lubrication method (grease or oil bath) of the Horizontal Split Casing Pump directly impacts the simplicity and reliability of routine maintenance, especially under harsh or high-temperature conditions.

What is the Pump’s Net Positive Suction Head Required (NPSHr)? How is Cavitation Avoided?

NPSH (Net Positive Suction Head) is a key technical parameter for high-head, high-flow pumps to prevent cavitation.

B2B engineers need to know the specific NPSHr value at various flow points and will inquire whether the manufacturer offers design options like first-stage impeller optimization or an inducer to lower the system’s required NPSHa (Available). Ensuring the pump runs stably under existing suction conditions is essential for project success.

What are the Vibration and Noise Levels of the Pump?

For municipal water supply, HVAC systems, or industrial sites with environmental restrictions, vibration and noise are critical indicators of equipment quality and environmental impact.

Customers will ask for the Horizontal Split Casing Pump‘s vibration velocity and noise level at the rated operating point. They will also be interested in whether the manufacturer offers low-vibration designs, vibration isolation pads, or acoustic enclosures to meet strict environmental or building codes.

What are the Design and Installation Requirements for the Baseplate?

The baseplate design for a large Horizontal Split Casing Double Suction Pump is vital for its long-term stability.

Customers will ask if the baseplate is a single-piece, adjustable design, and if it effectively absorbs vibration and maintains the alignment accuracy between the pump and motor. They will also seek information on specific anchor bolt sizes, foundation requirements, and grouting procedures to ensure accurate and durable on-site installation.

What is the Estimated Life Cycle Cost (LCC) of the Product?

Savvy B2B buyers and engineers focus not only on initial capital expenditure (CapEx) but, more importantly, on the Life Cycle Cost (LCC).

They will request the manufacturer to provide an LCC estimation model that accounts for: initial purchase price, energy consumption (the largest factor), annual maintenance costs, spare parts replacement frequency, and downtime losses. A high-efficiency, low-maintenance design can prove its long-term economic value and ultimately influence the customer’s choice.

Choosing the Right Double Suction Split Casing Pump for Your Project

Selecting a Horizontal Split Casing Double Suction Pump isn’t just about specifications—it’s about choosing reliability, efficiency, and long-term performance.

By understanding flow requirements, materials, energy consumption, and after-sales support, industrial buyers can confidently choose the right Double Suction Split Casing Pump for their systems.

A trusted Industrial Pump Manufacturer can provide the engineering support, customization, and testing needed to guarantee high-quality solutions for water supply, HVAC, fire-fighting, and industrial circulation projects.

As a premier Split Casing Pump Supplier, Shanghai Yimai’s double suction design ensures exceptional hydraulic balance and minimal axial thrust, resulting in prolonged service life. Our state-of-the-art Double Suction Pump Factory manufactures robust units ideal for large-volume water supply, HVAC systems, and industrial circulation. Partner with us for efficient, stable, and low-maintenance pumping solutions that reduce your total cost of ownership.

About Us

Founded in 2009 in Shanghai, Shanghai Yimai Industrial Co., Ltd. is a leading high-tech enterprise innovating at the intersection of water supply and environmental protection.

Our 60,000-square-meter manufacturing and R&D hub in the Jinshan District is powered by over 300 experts, making us a driving force in the industry. Yimai has earned top-tier recognition as a National-Level Specialized and Innovative “Little Giant” Enterprise and a Shanghai Famous Brand. Our deep technical expertise is proven by our involvement in editing six national industry standards and an impressive intellectual property portfolio of 15 invention patents, 60 utility model patents, and 39 software copyrights.

We provide complete, one-stop integrated solutions, from the core mechanics to intelligent systems. Our extensive product portfolio includes booster water systems, integrated precast pump stations, modular intelligent water plants, advanced sewage and oil-water separation systems, and robust solid waste treatment machinery (such as shredders and continuous presses).

At Yimai, our mission is clear: to deliver a high-quality, energy-efficient, and intelligent water environment. We are dedicated to the continuous pursuit of a cleaner, brighter tomorrow, ensuring water safety, stability, and purity for all. We are always by your side.