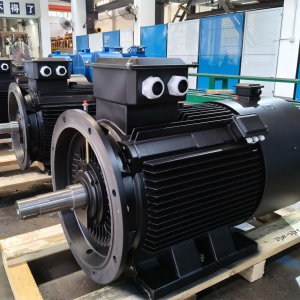

Why Permanent Magnet Electric Motor Stand Out: Efficiency, Power, and Durability

Legacy electric motors account for approximately 60% of industrial electricity consumption, operating at IE3 efficiency (94%) but wasting up to 30% of energy under light-load conditions. In response to global carbon neutrality goals, the Yimai permanent magnet electric motor achieves IE5 efficiency (98%) and near-unity power factor through rare-earth rotor technology—reducing energy consumption by 30% and serving as a key enabler of industrial decarbonization.

1.Ultra-high energy efficiency

The permanent magnet motor meets the highest international efficiency standard (IE5), delivering 10%–40% energy savings compared to conventional asynchronous motors. It is particularly suitable for equipment requiring long-term continuous operation, such as water pumps and fans, significantly lowering electricity costs over time.

2.Low noise and high stability

The three-phase permanent magnet motor operates at noise levels below Class A specified in GB/T 29529, fulfilling stringent acoustic requirements in quiet environments such as residential buildings, hospitals, schools, and laboratories. With an optimized magnetic circuit design and high-precision bearings, its vibration amplitude is lower than industry standards, resulting in enhanced operational stability and a reduced equipment failure rate.

3.High power density

Compared with traditional asynchronous motors of the same power output, the Yimai permanent magnet motor features a more compact structure and lighter weight, saving valuable installation space and making it ideal for integration into space-constrained equipment. Its power range spans from 0.37 kW to 450 kW, supporting customized configurations for diverse applications.

Our permanent magnet synchronous motor series includes two types: the standard type (compatible with frame sizes of conventional three-phase asynchronous motors) and the high-power-density type (with reduced frame sizes by 1–2 levels). This product line effectively supports both new industrial projects and energy-saving retrofits, with flexible customization options tailored to customer specifications. When your production lines integrate Yimai’s cutting-edge technology, we co-create not only motion but also boundless possibilities for industrial and planetary sustainability!

Keywords:

permanent magnet electric motor,permanent magnet motor,permanent magnet synchronous motor