Why Water Pump Efficiency Drops Over Time: Causes, Impacts, and Solutions for Optimal Performance

Water pumps are critical components in numerous industrial and municipal systems, ensuring the smooth operation of fluid transfer processes. However, a common challenge faced by operators and engineers is the gradual decline in water pump efficiency over time. This degradation leads to increased energy consumption, higher operational costs, and potential system failures. Understanding the root causes of this efficiency drop is essential for implementing effective maintenance strategies and optimizing system performance. We delve into the primary factors contributing to reduced pump efficiency and offer actionable insights for mitigation.

Understanding the Mechanisms Behind Decreased Pump Performance

The operational lifespan of a water pump is directly linked to its sustained efficiency. Several interconnected factors contribute to the decline in a pump’s ability to convert input energy into hydraulic power. These factors often manifest subtly, making early detection crucial for preventing significant performance losses.

Cavitation: The Silent Destroyer of Impellers

Cavitation occurs when pressure within the pump drops below the vapor pressure of the liquid, forming vapor bubbles. These bubbles collapse violently when they encounter higher pressure zones, creating shockwaves that erode pump components, particularly impellers and casings. This erosion alters the impeller’s hydraulic profile, reducing its ability to move fluid efficiently. Early signs of cavitation include noise, vibration, and a noticeable drop in flow rate or pressure. Prolonged cavitation can lead to severe mechanical damage, necessitating costly repairs or premature pump replacement.

Erosion and Corrosion: Material Degradation Over Time

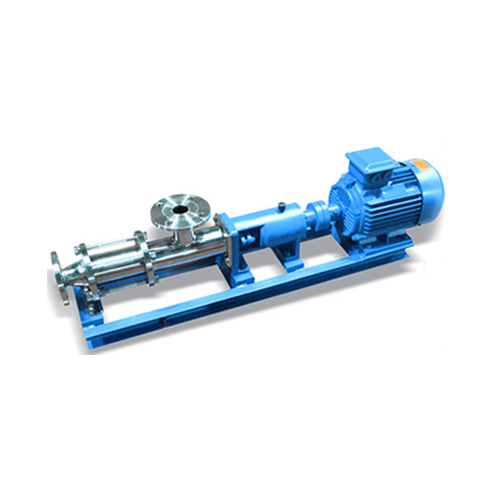

Erosion, caused by abrasive particles in the pumped fluid, and corrosion, resulting from chemical reactions between the fluid and pump materials, are significant contributors to efficiency loss. Over time, these processes wear away internal surfaces, increasing clearances between rotating and stationary parts. Increased clearances allow fluid to recirculate within the pump, bypassing the discharge and reducing net flow. This directly impacts the pump’s volumetric efficiency. The choice of materials, such as stainless steel for corrosive applications, can significantly extend pump life and maintain efficiency. For example, our Stainless steel single screw pump is designed with SUS304 and SUS316 materials to resist such degradation.

Mechanical Wear and Tear: Bearings, Seals, and Impeller Rings

Moving parts within a pump, such as bearings, mechanical seals, and wear rings, are subject to continuous friction and stress. Wear in these components leads to increased vibration, misalignment, and internal leakage. Worn wear rings, in particular, increase the gap between the impeller and the casing, allowing more fluid to slip back to the suction side, thereby reducing the pump’s head and flow capacity. Regular inspection and replacement of these wear parts are fundamental to maintaining optimal performance.

Operational Factors Impacting Pump Efficiency

Beyond inherent mechanical issues, several operational aspects can significantly influence a water pump’s long-term efficiency. These factors often relate to how the pump is integrated into the larger system and how it is managed.

System Design and Misapplication

An improperly sized or selected pump for a specific application will inherently operate inefficiently. If a pump is designed for a higher flow rate or head than required, it will operate off its Best Efficiency Point (BEP), leading to increased energy consumption and accelerated wear. Conversely, an undersized pump will struggle to meet demand, leading to continuous operation at maximum load, which also reduces efficiency and lifespan. Proper system design and pump selection are critical initial steps. Consider our article 《Picking the Right Water Pump: A Step-by-Step Selection Guide》 for more details on pump selection.

Inadequate Maintenance Practices

Lack of routine maintenance is a primary driver of efficiency decline. Neglecting tasks such as lubrication, seal replacement, and impeller cleaning allows minor issues to escalate into major problems. For instance, clogged impellers due to debris accumulation directly impede fluid flow, requiring the pump to work harder to achieve the desired output. A proactive maintenance schedule can significantly extend the operational life and efficiency of pumping systems.

Variable Operating Conditions

Pumps often operate under fluctuating demand, requiring frequent adjustments to flow or pressure. If a fixed-speed pump is used in a variable-demand system, throttling valves are often employed to control flow. This method wastes energy, as the pump continues to operate at full power while the valve restricts output. Variable Frequency Drives (VFDs) offer a more energy-efficient solution by adjusting motor speed to match demand. Our VFD Controlled Booster System can optimize energy usage by up to 40% in such scenarios.

The Financial and Environmental Impact of Inefficient Pumps

The degradation of water pump efficiency carries substantial financial and environmental consequences for industrial facilities and municipal utilities. Ignoring these issues can lead to escalating costs and increased carbon footprint.

Increased Energy Consumption and Operational Costs

As pump efficiency drops, the amount of electrical energy required to move a given volume of fluid increases. Even a few percentage points of efficiency loss can translate into thousands of dollars in additional electricity bills annually, especially for large-scale operations. For example, a 10% drop in efficiency for a pump consuming 100 kW continuously can result in an extra 87,600 kWh per year, significantly impacting the bottom line. This financial strain underscores the importance of maintaining optimal pump performance.

| Efficiency Loss (%) | Annual Energy Cost Increase (USD) | Environmental Impact (CO2 tons) |

|---|---|---|

| 5% | $2,500 | 15 |

| 10% | $5,000 | 30 |

| 15% | $7,500 | 45 |

| 20% | $10,000 | 60 |

Assumptions: 100 kW pump, 8,760 operating hours/year, $0.10/kWh, 0.6 kg CO2/kWh.

Reduced Reliability and Increased Downtime

Inefficient pumps often experience higher stress on their components, leading to more frequent breakdowns and unscheduled downtime. This not only incurs repair costs but also disrupts critical processes, potentially leading to production losses or service interruptions. For industries reliant on continuous fluid transfer, such as manufacturing or water treatment, reliability is paramount. Investing in high-quality, durable pumps and proactive maintenance minimizes these risks.

Environmental Footprint

The increased energy consumption from inefficient pumps directly contributes to a larger carbon footprint. As industries worldwide strive for sustainability, optimizing pump efficiency becomes a key strategy for reducing greenhouse gas emissions. Implementing energy-efficient solutions, such as those offered by Shanghai Yimai Industrial Co., Ltd., supports environmental stewardship. For instance, our article 《Building an Energy-Efficient Water Pumping System》 explores various strategies for reducing environmental impact.

Strategies for Maintaining and Improving Water Pump Efficiency

Proactive measures and technological advancements offer significant opportunities to counteract the natural decline in water pump efficiency. Implementing a comprehensive strategy can lead to substantial long-term savings and improved system reliability.

Regular Monitoring and Predictive Maintenance

Implementing a robust monitoring system, including vibration analysis, temperature checks, and flow/pressure measurements, allows operators to detect early signs of efficiency degradation. Predictive maintenance, which uses data analytics to forecast potential failures, enables timely interventions before minor issues escalate. This approach minimizes unexpected downtime and optimizes maintenance scheduling.

Upgrading to High-Efficiency Pumps and Motors

Replacing older, less efficient pumps with modern, high-efficiency models can yield significant energy savings. Contemporary pumps are designed with advanced hydraulics and materials that resist wear and cavitation more effectively. Pairing these with high-efficiency motors, such as IE4 Three-Phase Electric Motor or IE3 Three-Phase Electric Motor, further enhances overall system efficiency. Upgrading to an Intelligent Digital Driven VFD Booster System can also provide real-time optimization.

Optimizing System Design and Operation

Revisiting the original system design to ensure pumps are operating at or near their BEP is crucial. This may involve rightsizing pumps, adjusting piping configurations, or implementing variable speed controls. For systems with fluctuating demand, VFDs are particularly beneficial, allowing the pump to match its output precisely to the system’s needs, thereby conserving energy.

Material Selection and Protective Coatings

Choosing pump materials that are resistant to the specific fluid’s corrosive or abrasive properties is vital. In some cases, applying specialized coatings to impellers and casings can provide an additional layer of protection against erosion and corrosion, prolonging the pump’s hydraulic integrity and efficiency.

Shanghai Yimai Industrial Co., Ltd.’s Commitment to Sustained Efficiency

At Shanghai Yimai Industrial Co., Ltd., we understand the critical importance of maintaining water pump efficiency over time. Our product development and engineering philosophy are centered on delivering solutions that offer long-term reliability, minimal operational costs, and superior performance. We leverage advanced manufacturing techniques and stringent quality control to ensure our pumps and related systems meet the highest industry standards.

Our range of products, from Single stage end suction volute pump to Vertical Multi-Stage Centrifugal Pump, integrates features designed to combat efficiency degradation. For instance, our pumps often incorporate robust mechanical seals and wear-resistant materials, extending their operational life even in demanding environments. Furthermore, our intelligent control systems, like the Intelligent Digital Driven VFD Booster System, actively manage pump operation to maintain optimal efficiency despite varying system demands.

We also offer comprehensive support and expertise to help our clients select the right pump for their specific needs, ensuring proper application and preventing premature efficiency drops. Our commitment extends to providing guidance on maintenance best practices, helping operators maximize the lifespan and performance of their pumping infrastructure.

Expert Insight

Maintaining water pump efficiency is not merely a maintenance task; it is a strategic investment in operational sustainability and cost reduction. Our experience shows that a significant portion of energy waste in fluid transfer systems stems from overlooked efficiency degradation. By focusing on predictive maintenance, proper pump selection, and adopting modern technologies like VFDs, organizations can achieve substantial energy savings. For example, implementing a VFD-controlled system can reduce energy consumption by up to 40% compared to traditional throttling methods, directly translating into lower operating costs and a reduced environmental footprint. This holistic approach ensures that pumping systems remain reliable and cost-effective throughout their operational life.

Contact Our Specialists

Are you experiencing declining water pump efficiency? Do you want to optimize your fluid transfer systems for better performance and lower costs? Contact our specialists today to explore tailored solutions and discover how Shanghai Yimai Industrial Co., Ltd. can help you achieve sustained efficiency and reliability. We are ready to assist with expert advice and high-quality products.

FAQs

Q1: What are the most common reasons why water pump efficiency drops over time?

A1: The most common reasons include cavitation, erosion, corrosion, mechanical wear of components like bearings and seals, improper system design, and inadequate maintenance practices. Each of these factors contributes to internal leakage and hydraulic losses, leading to a decline in water pump efficiency.

Q2: How can I detect early signs of reduced pump efficiency?

A2: Early detection involves monitoring key performance indicators such as flow rate, discharge pressure, power consumption, and vibration levels. A noticeable decrease in flow or pressure at constant power input, or an increase in power consumption for the same output, indicates a drop in water pump efficiency.

Q3: What role does proper pump selection play in long-term efficiency?

A3: Proper pump selection ensures the pump operates close to its Best Efficiency Point (BEP) under normal operating conditions. A pump that is correctly sized for the application will experience less wear, consume less energy, and maintain its water pump efficiency for a longer period, avoiding issues like cavitation and excessive throttling.

Q4: Can upgrading pump components improve efficiency?

A4: Yes, upgrading worn components such as impellers, wear rings, and seals with higher-quality, more durable materials can significantly restore and improve water pump efficiency. Additionally, integrating modern technologies like Variable Frequency Drives (VFDs) can optimize pump speed to match demand, further enhancing efficiency.

Q5: How does Shanghai Yimai Industrial Co., Ltd. ensure the long-term efficiency of its pumps?

A5: Shanghai Yimai Industrial Co., Ltd. ensures long-term water pump efficiency through advanced hydraulic designs, the use of corrosion-resistant and wear-resistant materials, stringent manufacturing quality control, and the integration of intelligent monitoring and control systems, such as our VFD Controlled Booster Systems, which optimize performance in real-time.

Keywords

Primary Keyword: Why Water Pump Efficiency Drops Over Time

Long-tail Keywords: pump efficiency degradation, industrial pump maintenance, optimizing fluid transfer systems, reducing pump operational costs

Semantic Keywords: cavitation, erosion, corrosion, mechanical wear, impeller, VFD, energy consumption, predictive maintenance, hydraulic performance, system reliability, pump selection, operational costs, environmental footprint