Choosing the right screw press for dewatering starts with a clear grasp of how the machine is built. We see, again and again, that the screw’s geometry and material set the tone for separation efficiency, cake dryness, and service life. When the screw is matched to the job, energy...

Industrial shredders carry a lot of weight in waste management and material processing. When they run within limits, uptime follows and safety risks drop. Overload protection is the quiet workhorse behind that reliability, from sensing strain to stopping damage before it spreads. Here, we walk through how detection works,...

Picking a shredder that holds up under real work starts with its protection systems. When those are designed well, performance stays steady and the machine avoids stress and surprise failures. We look at specifications, the materials being fed, the environment, and the output required to build safeguards that fit....

Getting particle size right on industrial shredders pays off in downstream performance and material value. When output drifts, bottlenecks appear, costs rise, and quality slips. We treat particle size control as a strategic lever for efficiency and profitability across industries, not a minor tweak. Our experience is straightforward: the...

Selecting the correct shredder power sets the pace for waste processing that actually runs as planned. When power is specified accurately, the machine keeps material moving without wasting energy or stalling. We match the shredder’s capability to the material in front of it and the output you need, because...

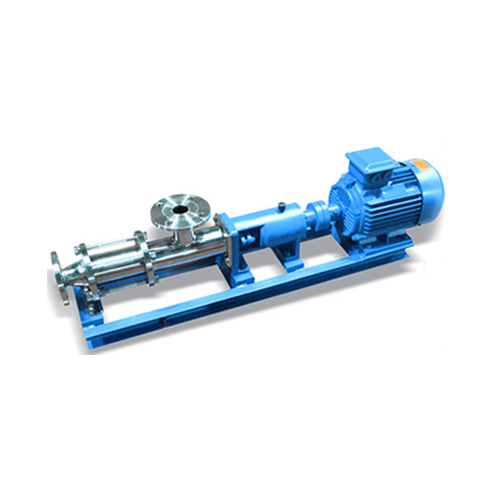

Selecting the optimal sludge dewatering technology can shape outcomes across industrial and municipal operations. We’ve seen how small choices in solid-liquid separation ripple through cost, compliance, and day-to-day reliability. Here, we compare dewatering presses and centrifuges, covering operational principles, performance metrics, economics, and where each tends to fit best....

We see the same problem play out across plants: wet sludge drives up costs, strains compliance, and complicates day-to-day operations. Dewatering sits at the center of that reality. When it underperforms, both budgets and permits feel it. When it works, disposal volumes drop, handling gets easier, and environmental risk...

Shredding complex industrial materials is seldom straightforward, and the risks are real. We routinely see how diverse waste streams and hazardous components raise the stakes, from potential explosions and entanglement hazards to exposure to harmful dust. That mix calls for robust safety measures. From experience, treating these dangers as...

Managing industrial solid waste is complex work that blends regulation, risk, and real opportunities for recovery. From what we’ve seen, results improve when the whole chain is treated as one system: collection and segregation, pre-treatment, advanced physical, chemical, biological, and thermal processes, then resource recovery and final disposal. This...

Efficient waste management shapes costs, safety, and sustainability across many operations. Dual-shaft shredders cut waste volume and ready materials for recycling or disposal, and knowing how they work helps systems run smoother and last longer. We cover their core design and process, where they outperform other options, real-world applications,...